Steel. The most important construction material in the world. Now for construction, it is most of the time irrelevant to apply a polished finish or create a bright annealed or reflective surface,. Of course, the burrs need to be gone. But that is what steel deburring is for. So what about creating a steel surface finish? Well, does that even exist? A mill finish on steel is actually no more than a pre-treatment for coating or painting. This metal easily rusts which is why it -almost- always gets a surface treatment afterwards.

The right machine tool for finishing steel

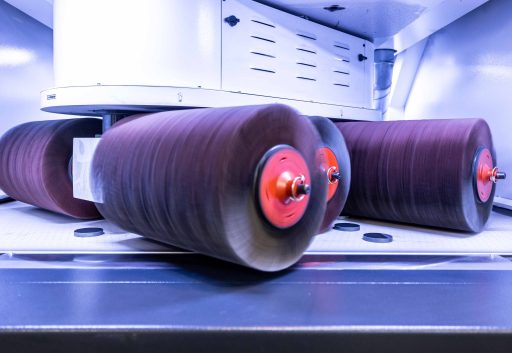

Steel parts and sheets can be deburred and grinded by any Timesavers machine. The wide range of deburring machines starts with an entry level model for small volume production. It extends to large rotary brush machines that provide deburring, rounding and finishing of multiple steel parts simultaneously. An ultimate solution for sheet metal finishing.

If it comes to grinding steel sheets, plates or coils, a heavier machine is required. The Timesavers finishing machines are built to perform day-in, day-out and year-in, year-out. These are the grindingmasters. A wet working 71 series or a dry working 62 or 72 series? The choice is yours!

The coil-to-coil line at BTH Import Steel

The coil-to-coil line at BTH Import Steel

Poland-based BTH Import Stal has shared their experience with the 71 series finishing machines. They are capable of producing several steel surface finishes on their coils and have an unmatched flexibility to deliver on their promises.

Contact our specialists

Contact our specialists

From manual grinders to multifunctional deburring- and finishing machines tailored to all needs, Timesavers has a solution for every metal working application. Our Timesavers specialists are always ready to answer your questions.

SURFACE ROUGHNESS

The measured value for surface roughness is Ra, Rz or Rt. It determines how smooth the surface of the material is, in this case after steel grinding. The value is always measured on a test length. This means that the value may vary slightly depending on where the measuring device is placed on the surface. If you would like to learn more about measuring surface roughness, you should take a look at the article in our knowledge base.

All you need to know about surface roughness (Ra)

All you need to know about surface roughness (Ra)

When working in metal finishing industries, you have most certainly heard about surface roughness. It measures the irregularities on metal surfaces. Now what measurements are there? And why is it important?

Types of metal finishes for steel

Cold rolling steel makes a smoother mirror finish than hot rolling. This is why the starting point of cold rolled steel is a finish no. 2 and for hot rolled no. 1. These types of metal finishes for steel are not enough to apply a coating on. Just like any other material that needs to be painted, you start with roughing up the surface. It promotes adhesion, because rough surfaces have more profile than smooth mill finishes.

Tooling for steel finishing processes

The tooling that Timesavers uses for grinding are abrasive belts and brushes. These come in many grit sizes ranging from #36 up to #400. A coarse belt can be perfect for a coating to adhere, but eventually the choice of belt or brush really depends on the surface requirements or the type of paint. With the right belt, the right speed and the right pressure, we can help you achieve that desired metal finishes for steel.

More information about Timesavers Tooling

More information about Timesavers Tooling

Would you like to know more about our tools for deburring and finishing sheet metal? The experienced spare parts department at Timesavers is always ready to answer your questions!

The importance of quality management when finishing steel

It is of crucial importance to maintain a high quality finish when processing steel or stainless steel. A bad finish can lead to problems such as decreased corrosion resistance. This is the reason why it is advisable to use machinery that is exclusively of the highest quality, especially for applications where a high quality product is necessary. These applications include industries such as the medical or aerospace industry. In conclusion, finishing steel is a highly important process, necessary to increase the sustainability and aesthetics of the material.

Safety during finishing of steel

As the steel surface finish process involves the use of deburring brushes and grinding belts under high pressures and speeds, metal dust and splinters are an unavoidable byproduct. Because of this, it is of crucial importance to maintain a safe and clean working environment.

Timesavers, in collaboration with Absaugwerk GmbH, offers reliable extraction units that are perfectly compatible with your Timesavers machine, ensuring a safe and clean working environment. Apart from the powerful Absaugwerk extraction units, it is important to clean your Timesavers machine regularly, because not all metal dust can be caught with an extraction unit. All Timesavers machines have a built-in automatic cleaning cycle which is activated once the machine is turned off. If your machine runs continuously, the cleaning cycle is activated every 4 hours, even when using the machine 24/7. To ensure maximum cleanliness of your machinery, Timesavers also offers exclusive cleaning products.

CONCLUSION

Steel finishing and the finishing of other metals such as aluminium, stainless steel and copper are crucial steps in metalworking to achieve the desired surface finish and precision. At Timesavers International, we offer world-class finishing and deburring machines that are capable of processing steel and other metals with high precision. Our machines are versatile, efficient and offer quality and precision that is second to none. We customise our solutions to your specific requirements and place great emphasis on environmental protection and sustainability.