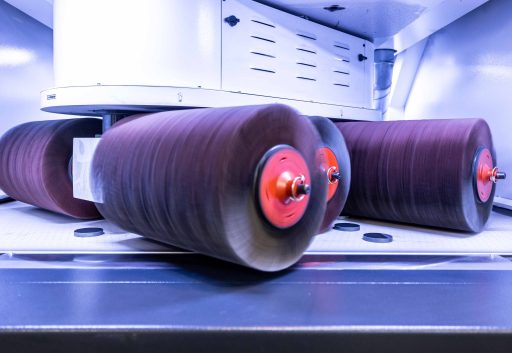

Timesavers grinding belts provide consistent, reliable performance on various substrates. The abrasive belts can be used for heavy grinding applications like burr removal and finishing. Whether you need a solution for deburring, finishing, or grinding, our belts provide the right solution for any situation.

To ensure the best results of our deburring and finishing machines, we have partnered up with 3M to provide the highest quality grinding belts for our customers. 3M is a worldwide supplier of abrasive belts and they have proved themselves as a leading innovator and creator of effective solutions to multiple industries.

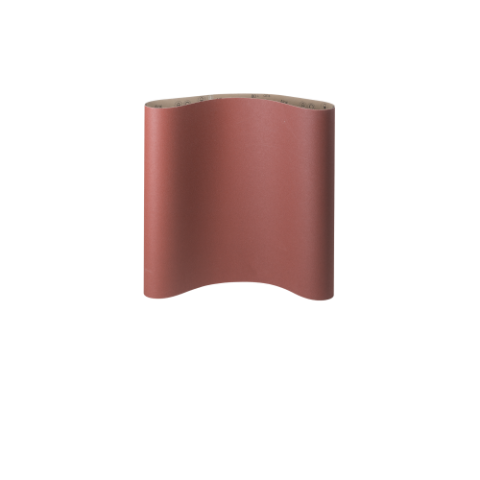

3M™ CUBITRON™ II CLOTH BELT 384F

3M™ Cloth Belt 384F is a general purpose, premium aluminium oxide cloth belt with an extra durable backing. The abrasive sanding belt features fastcutting abrasive grains that are resin-bonded to a durable X-weight polyester cloth backing. They are recommended for use on metal substrates and wood.

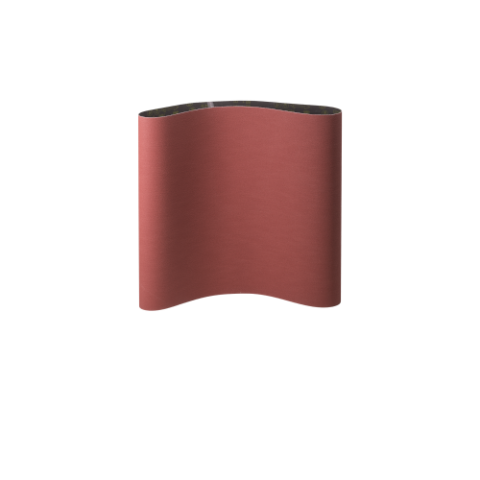

3M™ CUBITRON™ II CLOTH BELT 784F

3M™ Cubitron™ ll Cloth Belt 784F features 3M Precision Shaped Grain. Our ceramic sanding belts are a precise mix of shaped ceramic and premium aluminium oxide. They have a flexible J-weight cotton backing and open coat construction. The sanding belts also feature a waterproof backing and grinding aid. Precision-Shaped Grain wears evenly to provide exceptional durability with remarkable consistency. As the grain wears, the ceramic sanding belt continuously fractures to form sharp points and edges that slice cleanly through the material.

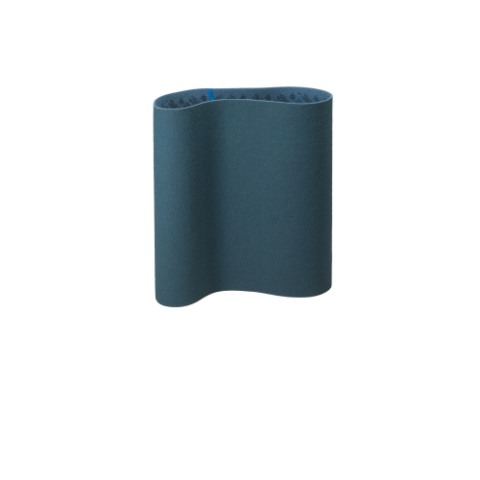

3M™ CUBITRON™ II CLOTH BELT 984F

3M™ Cubitron™ II Cloth Belts 984F offer revolutionary performance with 3M Precision Shaped Grain that slices clean through metal. Our 984F Timesavers deburring belts contain a abrasive belt grinder aid, making it ideal for medium to high pressure applications. Precision-Shaped Grain wears evenly to provide exceptional durability with remarkable consistency. As the grain wears, it continuously fractures to form sharp points and edges that slice cleanly through the material.

OUR GRINDING BELTS FOR DEBURRING

3M™ CLOTH BELT 461F

3M™ Cloth Belt 461F is constructed of sharp silicon carbide abrasive that fractures easily and consistently produces an excellent finish for the duration of the abrasive sanding belt life. This resin-bonded abrasive sanding belt gives you flexibility, durability, and consistent performance for grinding, blending, deburring, and finishing on all metals.

SCOTCH-BRITE™ SURFACE CONDITIONING LOW STRETCH BELT SC-BL

For cleaning, finishing and light deburring use our durable and flexible Scotch-Brite™ Surface Conditioning Low Stretch Belt. Our belt sanding belts offer effective cutting, while avoiding damage to substrates and are ideal for use on contoured and uneven surfaces. The belts perform best on steel, stainless steel, carbon, titanium, nickel alloys and may be used on aluminium, copper, brass and soft non-ferrous metals. They’re available in a wide range designed to suit a variety of different applications. Scotch-Brite Surface Conditioning Low Stretch belts are engineered with aluminium oxide and silicon carbide minerals.

Our grinding belts for finishing

More info? Contact us!

Timesavers’ experienced spare parts department is always ready to answer your questions.

APPLICATIONS OF OUR GRINDING BELTS FOR METALWORKING

Our extensive range of belt sanding belts for deburring offer a suitable solution for every problem. Our 384F aluminum oxide grinding belts offer good performance on all surfaces. For even faster results and longer abrasive sanding belt lifetime, the 784F mixed ceramic and aluminum oxide abrasive belts can be used. The highest results with the best abrasive belt grinder are achieved with the 984F precision shaped grain sanding belts.

We also offer the highest quality grinding belts for finishing. Our 461F silicon carbide grinding belt provides a perfect finish on all metals, but is most effective for deburring and finishing aluminum. For effective cutting and damage prevention on surfaces of various metals such as (stainless) steel, carbon, titanium, nickel, aluminum and copper, we offer the Surface Conditioning Low Stretch Belts of aluminum oxide and silicon carbide.