Second-hand machines

Mostly used by our customers for:

Deburring

/

Edge rounding

/

Edge rounding up to 2 mm radius

/

Finishing

/

Laser oxide removal

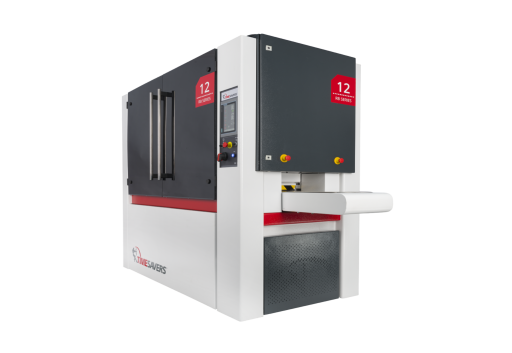

10 series

Mostly used by our customers for:

Deburring

/

Edge breaking

/

Finishing

/

Heavy slag removal

/

Laser oxide removal

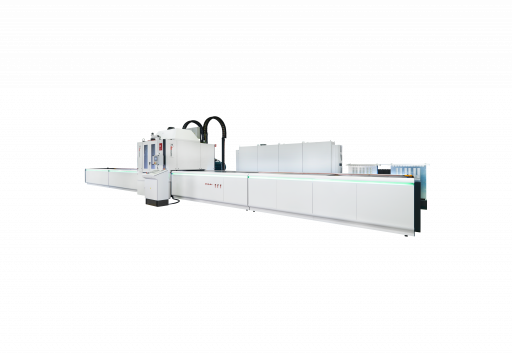

22 RB series

Mostly used by our customers for:

Deburring

/

Edge breaking

/

Edge rounding

/

Finishing

/

Laser oxide removal

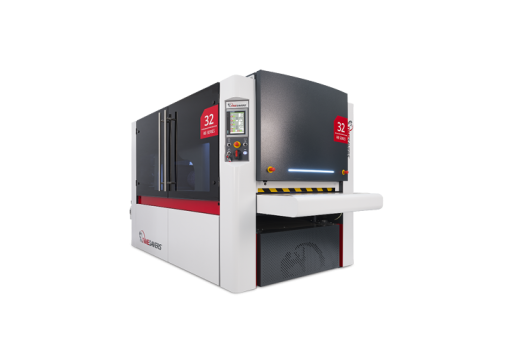

32 RB series

Mostly used by our customers for:

Deburring

/

Edge breaking

/

Edge rounding

/

Finishing

/

Heavy slag removal

/

Laser oxide removal

42 RB series

Mostly used by our customers for:

Deburring

/

Edge breaking

/

Edge rounding

/

Edge rounding up to 2 mm radius

/

Finishing

/

Heavy slag removal

/

Laser oxide removal