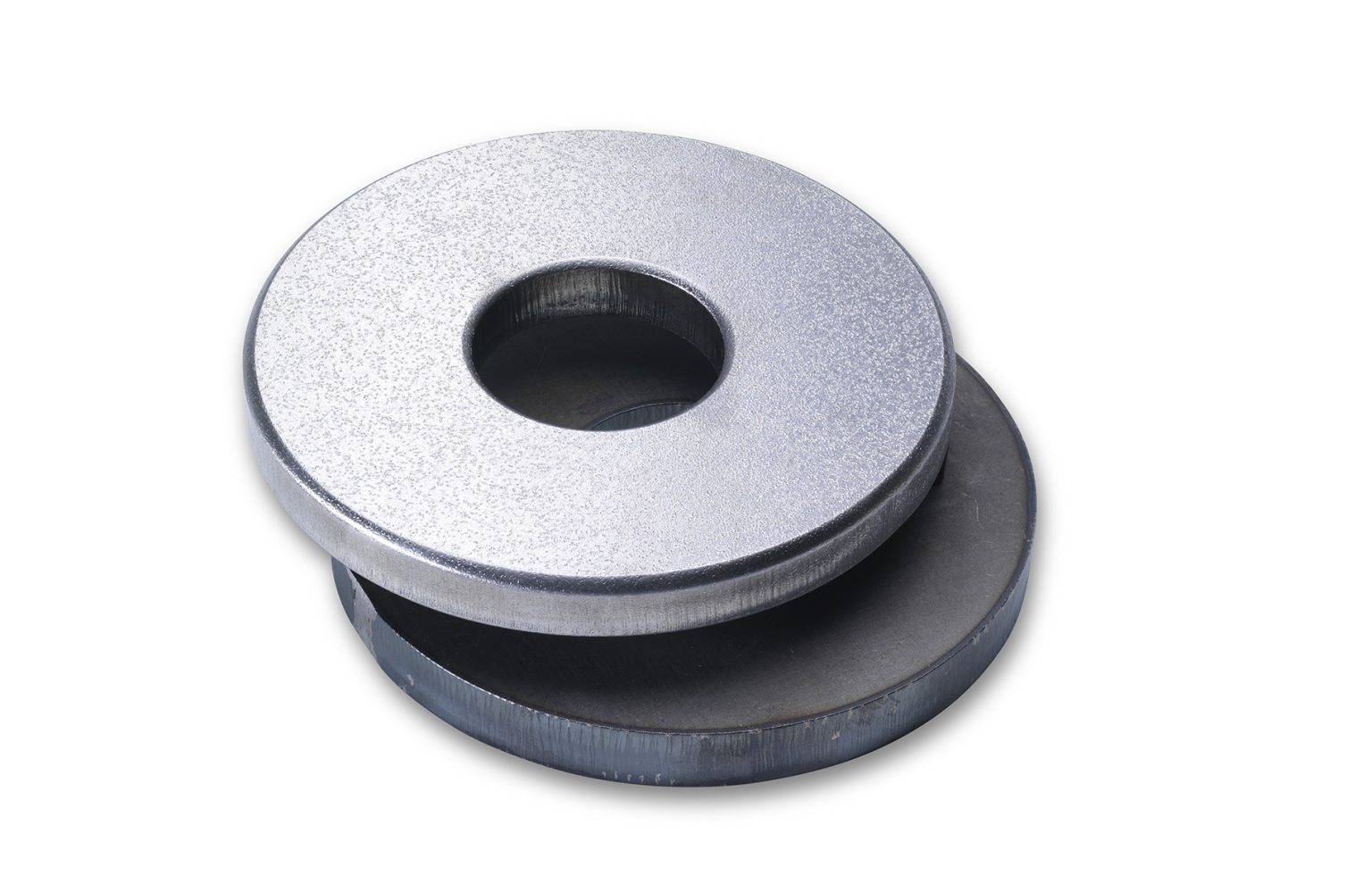

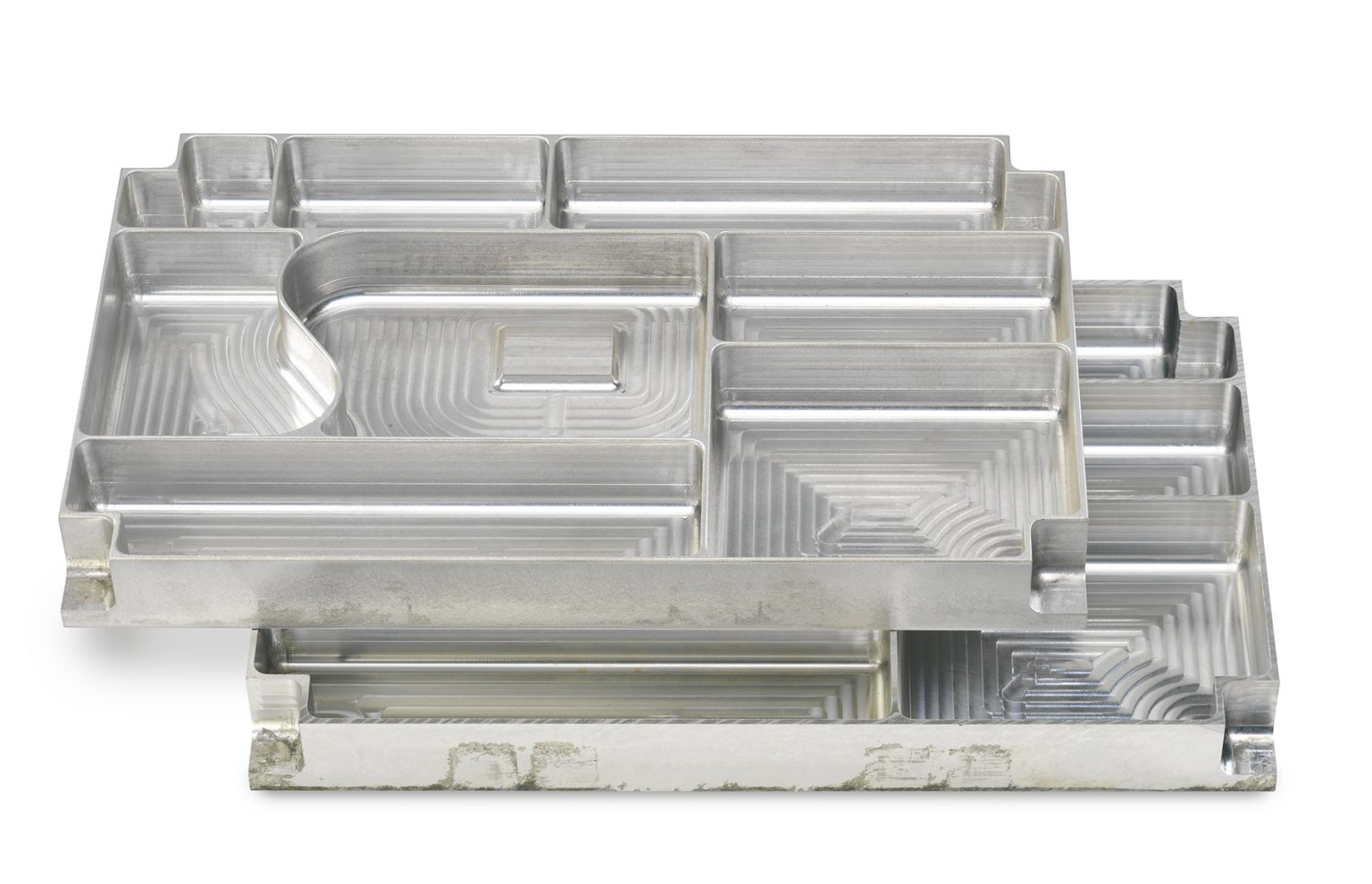

The 42 RB series is the perfect solution for uniform deburring, rounding and finishing of your products. The eight rotary brushes can achieve a radius of 2 mm on metals such as mild steel and aluminium. The machine can also process flat, shaped or 3D parts with protrusions using these brushes. Both small parts of 50 x 50 mm and large ones are held in place by a strong vacuum table.

42 series 1350 WRBW

This second-hand deburring machine is excellent for grinding and rounding sheet metal. With the construction year being 2017 and around 8,500 running hours on the counter, the machine can last for many years to come. The strong vacuum table makes it possible to process small products starting as small as 50 x 50 mm. The machine includes an Ulmatec wet working extractor (11 kW and H-14 filter) suitable for steel, stainless steel and aluminium.

- Frequency-regulated rollers (5-15 m/sec

- Frequency-regulated carousel (6-17 m/sec)

- vacuum table with automatic cleaning cycle

- Height read-out on HMI display of the brush unit, with 0 setting

- Pressure roller with over-thickness protection

- Wet working dust extraction unit Ulmatec NAS 7800-3 / 11 MD

- Ex works from Munich, Germany

Play

Play

Applications of the 42 RB series

Applications of the 42 RB series