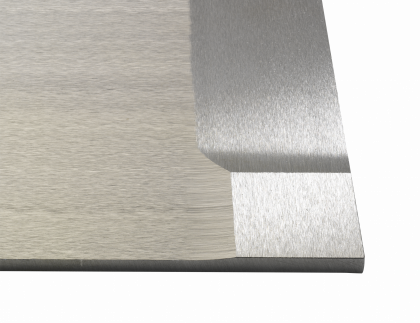

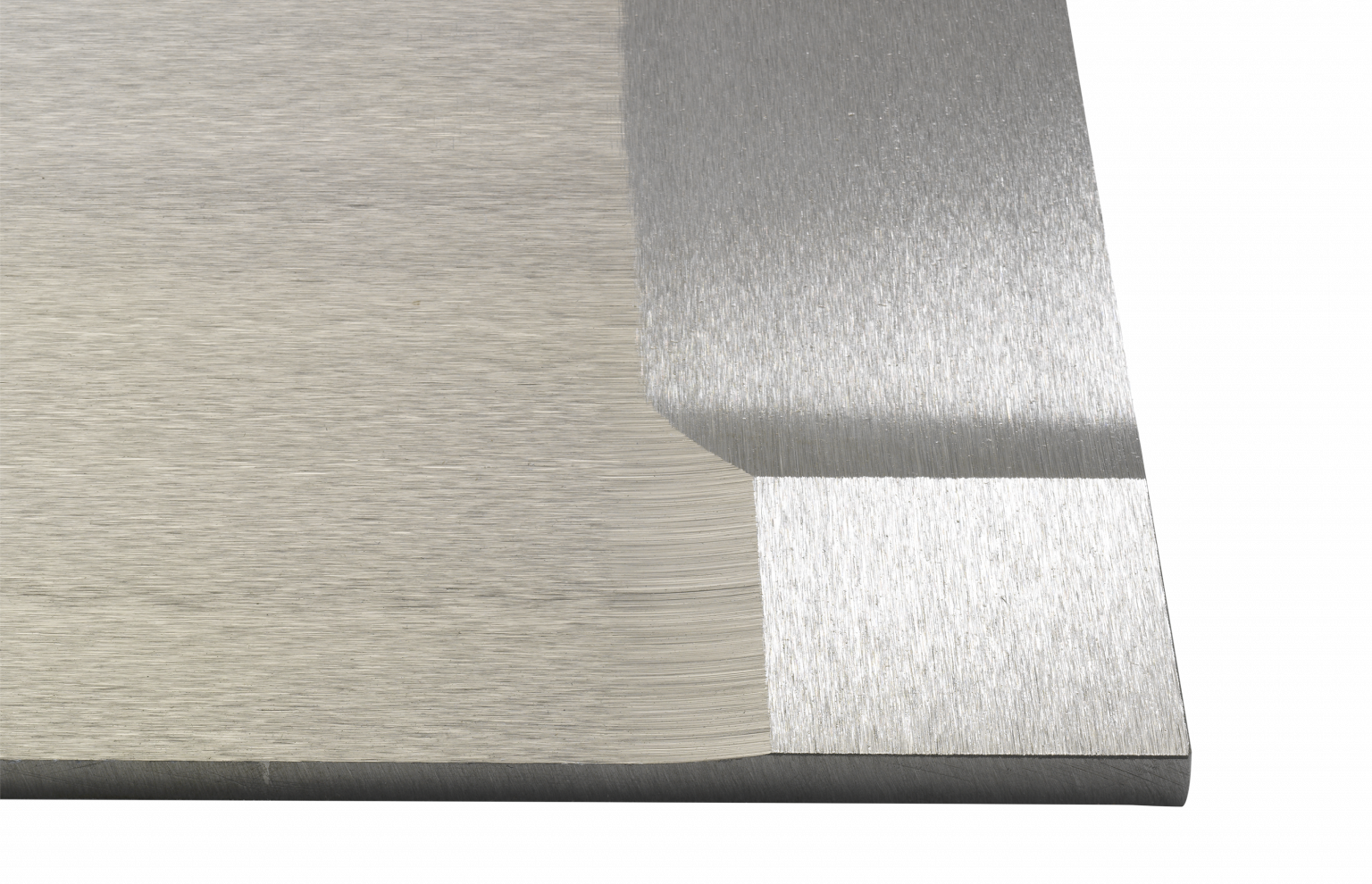

Precision grinding with Timesavers’ innovative grinding technology for the optimal results. Apart from flat surface grinding, it is possible to achieve a tapered or u-shaped surface on sheet metal. Abrasive belts are the best technique for accurate stock removal compared to milling and stone grinding, and more detailed information about this can be found in the knowledge base regarding precision grinding.

Your problem, our solution

Precision grinding with Timesavers’ innovative grinding technology

Precision grinding with Timesavers’ innovative grinding technology

Belt grinding is the most efficient choice because of the high surface quality, lower energy and tooling costs and a tight tolerance. A switch between high stock removal and fine finishing can be done by a fast tooling change. By working over the full width of the material in a cold process environment, low material tension will be added. Timesavers is the expert in precision grinding where tolerances of up to 0,02 mm can be achieved.

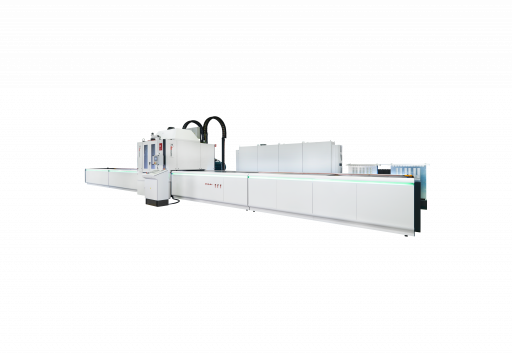

Precision grinding with Timesavers’ 81 Series

The 81 series is our precision grinding machine, that can be built according to your needs. The machine includes high precision grinding and surface finishing, so it is a complete solution that takes the product to the finished state. There are quite some widths available, ranging from 600 mm up to 2600 mm. The workpieces get machined to very close tolerances and high quality finishes.

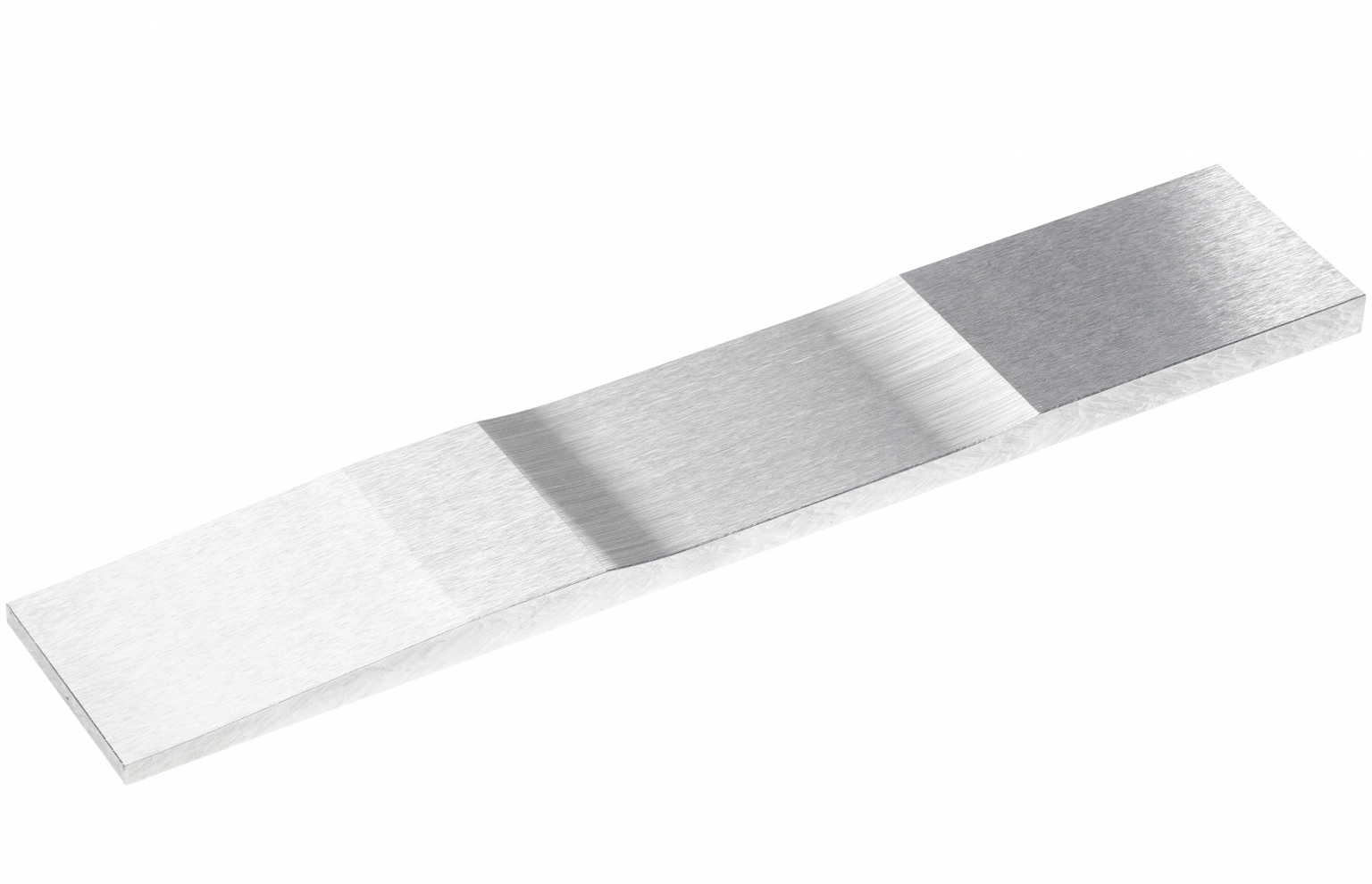

The wide range of parts from various metals that can go through the process of precision grinding include: titanium, stainless steel, steel, aluminium, zirconium or molybdenum and many more. This type of grinding results in a high quality surface. The work is often done for manufacturing industries related to Defense, aerospace or spacecrafts and rockets.

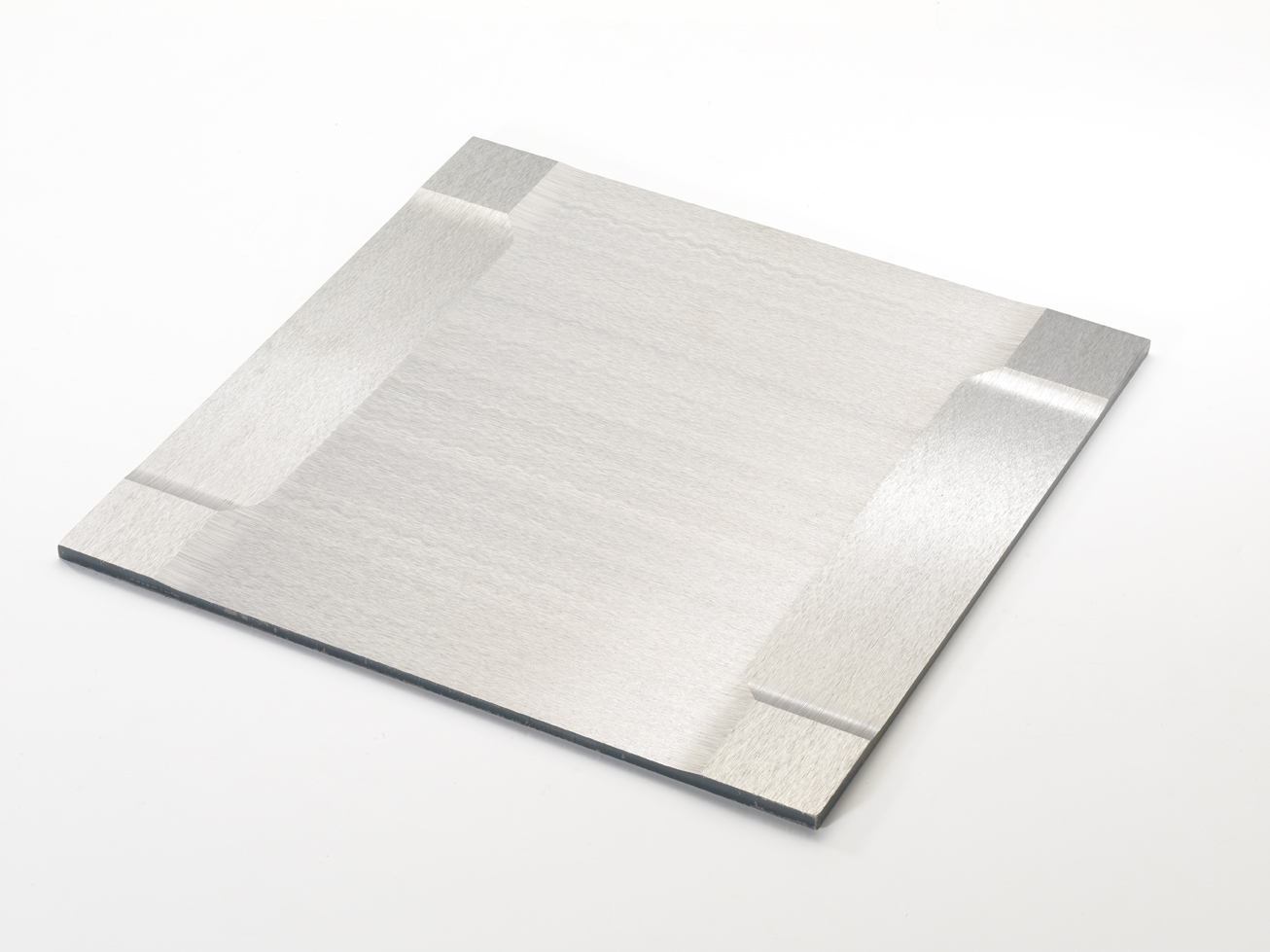

There is a diverse range of products that are made by the 81 series. In the following gallery, a handful of examples are shown that can be machined according to specification requirements:

Precision grinding in a variety of shapes and thicknesses

Precision grinding in a variety of shapes and thicknesses

What is the right solution for you?

By answering 5 simple questions, we lead you to the right machine.

FAQ about precision grinding

+

What is precision grinding?

Precision grinding is the grinding of metal to a predetermined thickness, either flat or in a U or tapered shape. One of the techniques to ensure precision is the use of abrasive belts that grind off layers from metal.

+

When is precision grinding needed?

Precision grinding has almost no heat input and is ideally for projects that need high tolerances.

+

What precision grind technique can be used for plates and parts?

Abrasive grinding belts ensure the best surface quality and are able to apply the needed energy when grinding. Not to mention that belts are easily being changed in between shifts and the costs of them are low.

+

What metals can be precision ground?

What metals can be precision ground?

It is possible to grind special alloys/metals such as aluminium, steel, stainless steel, titanium, molybdenum and zirconium.

+

Is it possible to precision grind Titanium to a specific thickness?

Yes, Titanium can be grind to a predetermined thickness and shape with a high surface quality.

+

Milling vs Precision grinding?

Although milling is a popular way of precision grinding, it does not as precise as grinding belts, nor does it leave the product with a high surface quality.