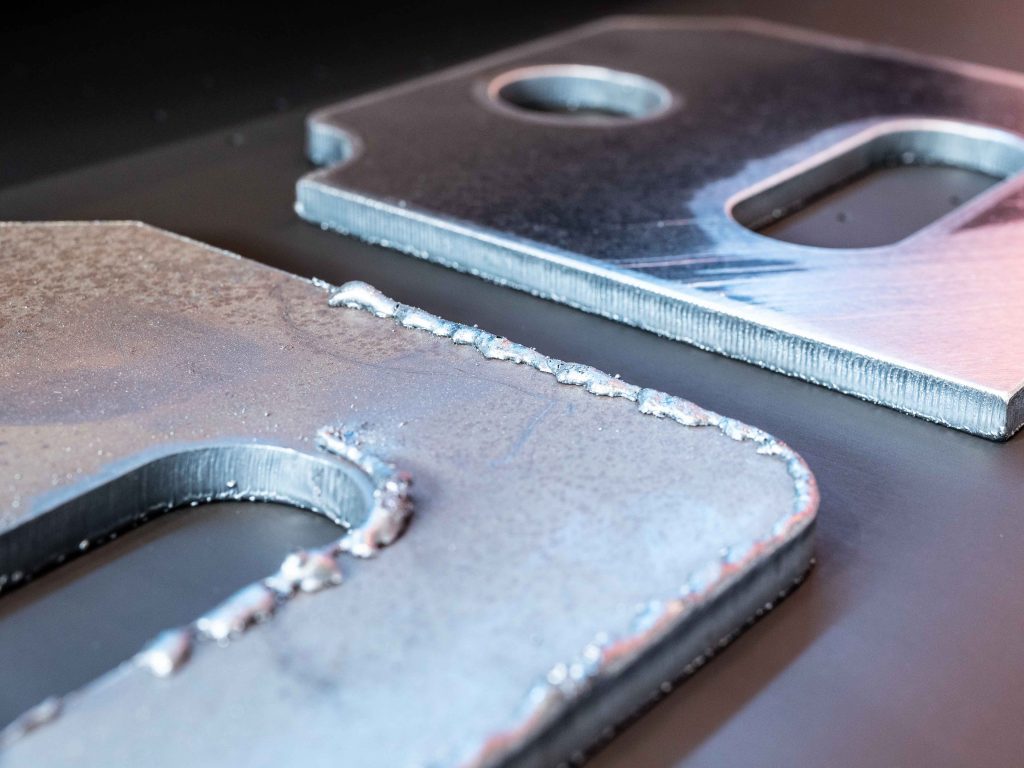

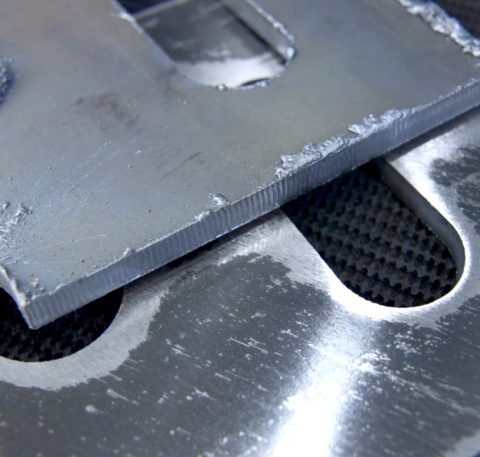

Heavy slag, also known as dross, is basically molten metal on parts that are produced during thermal cutting operations: oxy-fuel, flame cutting and plasma cutting. In order to remove the heavy slag on plasma or oxy-fuel cut parts, Timesavers developed the Hammerhead. More information can be read on the knowledge base page about heavy slag removal.

Your problem our solution

Save time with our solutions for plasma slag removal

Save time with our solutions for plasma slag removal

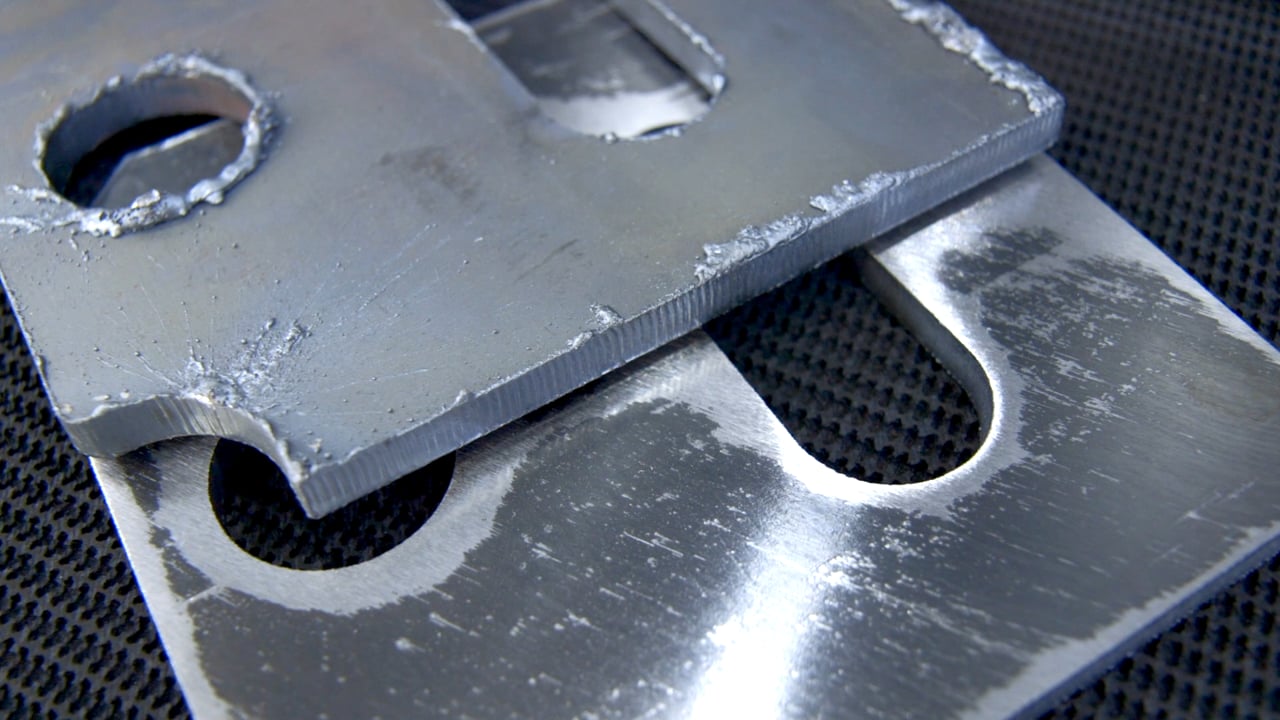

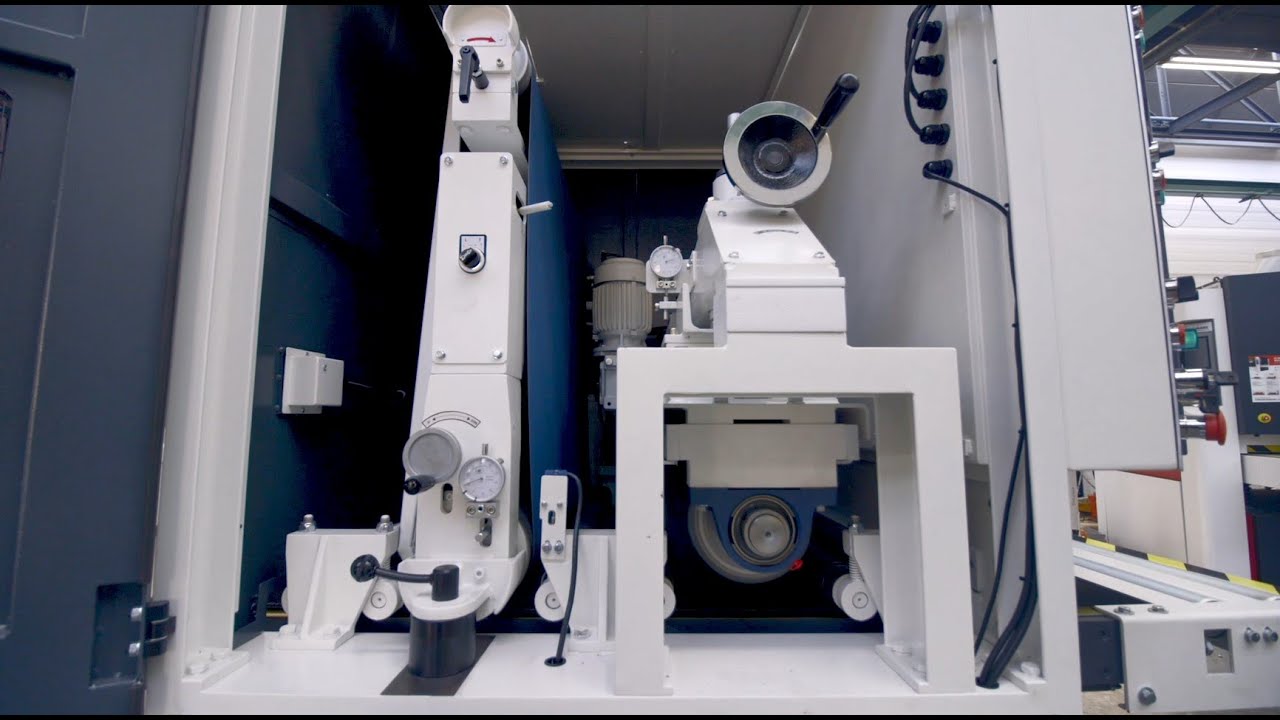

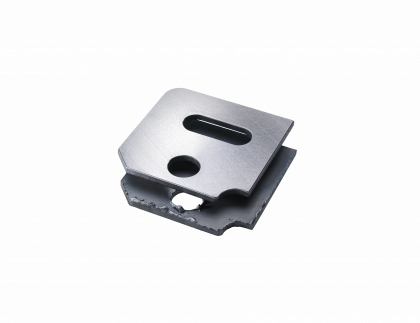

What normally would have been done with a chipping hammer or with the help from an angle grinder, is now done with the Hammerhead. The Hammerhead is available on four deburring machines: the 10, 22, 32 RB series and the 42 RB series. To ensure less downtime, the slide with pins can be reversed or the complete slide can be changed easy and fast.

The pins hammer the slag of the parts by an counterclockwise movement to guarantee an optimal dross removal. The Hammerhead is a fast and effective solution for the removal of heavy slag. Out of all power tools, the Hammerhead is capable of even removing heavy burrs. In need for slag grinding machines? Request a quotation via the link below.

Play

Play

What is the right solution for you?

By answering 5 simple questions, we lead you to the right machine for your application.

FAQ about slag removal

+

What is slag?

Slag, also known as dross, is a term used to describe metal residuals that have been melted to a part after it has been cut by thermal cutters, like plasma or oxy-fuel. This slag is tough and it takes force to remove it.

+

What is deslagging?

Deslagging is the removal of slag from metal parts by hand or with the use of a machine (tool).

+

How to remove dross or heavy slag?

Slag can manually be removed with a hammer or a knife, but it takes a lot of time and effort of the worker and the repetitive work can lead to injuries. A machine solution is the Hammerhead, that hammers off all dross within no time.

+

How can you optimise your process with a deslagging machine?

Deslagging products takes a lot of time and energy when done by hand. Therefore, a deslagging machine is great to optimise the process and increase productivity.

+

What deslagging solutions are there with Timesavers machines?

Timesavers offers machines of different sizes, so that there is a solution for every size of business. The 10 series is the smallest solution that uses a brush head with Hammerheads to hammer off the burrs. The 22 series is slightly larger and is equipped with the Hammerhead aggregate, just like the largest 42 RB series.