During thermal cutting of metal parts, done by flame, oxy-fuel or plasma cutters, there are small metal pieces that melt and adhere to the product when it cools down. These pieces of molten steel are found around the cutting edges of a part or product, also called metal dross or slag. It is preferred to remove the heavy slag.

Why should metal dross be removed?

- The slag does not contribute to the strength and protection of the metal, but is rather a form of waste.

- The slag formation does not look attractive nor professional from an aesthetic point of view.

- The metal slag makes it difficult to apply an adhesive coating to the surface.

How can dross be removed?

- Manually, this dross can be scraped off the metal with a hammer or knife. This intensive work is time-consuming and there is a risk of injury for the worker. After the slag is removed, a sanding machine is needed to make the surface smooth and to leave a nice finish.

- Mechanically, the removal of dross with a slag grinder or with the hammerhead is a fast and effective innovation. By oscillating in a countercurrent movement, the heavy slag is hammered off. The machinery can be equipped with an abrasive belt or finishing belt, so the parts are completely processed in one single pass.

The hammerhead aggregate

The hammerheads are especially developed for heavy slag removal. The aggregate consists of replaceable, flexible pins that hammer off the dross with an oscillation of 120 h/min. This guarantees a high quality removal process. They make the sheet metal components, whether those are made from stainless steel, steel, copper or aluminium, dross free.

Watch our video about the hammerhead on our Timesavers International YouTube channel.

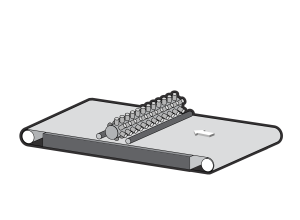

A component that is cut by plasma, could look like the following image, with slag around the cuts:

The machine configuration with only the hammerheads (H), will result in a workpiece that is dross free:

|

|

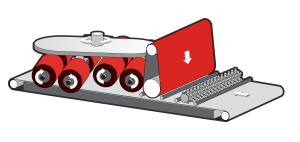

The belt can be added for additional edge breaking, which is the configuration HW:

|

|

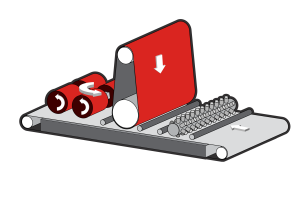

Another configuration is the HWRB, where slag is removed with the hammerheads, the part deburred by the belt and the edges are rounded by the rotary brushes and/or the oxide layer is removed. It leads to a perfect finished product:

|

|

Timesavers’ machines for heavy slag removal

Timesavers is specialized in deburring machines, edge rounding machines, precision grinding machines, finishing machines and of course heavy slag removal machines. For the latter, we offer the following series, ranging from small to large:

For a cost-effective alternative to manual slag removal, this machine is the right entry-level model. It is a table with two heads that can be fitted with the desired application brushes. The work is done 3 to 4 times faster compared to manual operation and a long service life of the material is guaranteed. It is the ideal machine for processing small parts, although larger parts are also possible thanks to the adjustable sides.

22 series – Rugged & Solid machine

This medium sized plasma dross removal machine uses the Hammerhead aggregate to remove the slag from flame or plasma cut parts. It is available in a working width of 900 mm, 1050 mm or 1280 mm. The machine can also remove vertical burr caused by punching, waterjet or laser cutting processes.

32 RB series – Rotary Brush machine

The 32 series with rotary brushes has a working width of 1100 mm and can be equipped with the Hammerhead solution. This makes the machine a compact, all-in solution for removing slag, deburring, edge rounding and finishing.

42 RB series – Rotary Brush machine

The largest machine is the 42 RB series, that is not only capable of removing the heavy slag from the surface with the Hammerheads, but also rounding the edges up to a radius of 2 mm with the rotary brushes. Another option is to equip the rotary brush with laser oxide removal brushes, which makes the product ready for welding or coating.

22 HW suitable for slag removal and finishing

42 HWRB suitable for all applications

Looking for a different solution for your sheet metals? We also have a range of deburring and edge rounding machines. Contact us for help and together we find your perfect machine solution with the desired functions.

About removing heavy slag

+

What is slag?

Slag, also known as dross, is a term used to describe metal residuals that have been melted to a part after it has been cut by thermal cutters, like plasma or oxy-fuel. This slag is tough and it takes force to remove it.

+

What is deslagging?

Deslagging is the removal of slag from metal parts by hand or with the use of a machine (tool).

+

How to remove dross or heavy slag?

Slag can manually be removed with a hammer or a knife, but it takes a lot of time and effort of the worker and the repetitive work can lead to injuries. A machine solution is the Hammerhead, that hammers off all dross within no time.

+

How can you optimise your process with a deslagging machine?

Deslagging products takes a lot of time and energy when done by hand. Therefore, a deslagging machine is great to optimise the process and increase productivity.