At Hanse Staalbouw in Nieuwerkerk, the Netherlands, you’ll see nothing but happy faces. The family-owned company, a specialist in the construction of complete commercial buildings in the agricultural, industrial and non-residential sectors, is always looking for ways to improve efficiency – and thanks to the 22 series with Hammerhead unit from Timesavers, it has been found.

In September 2018, Hanse became the first company in the world to start using the 22 series machine fitted with a Hammerhead unit – for the Zeelanders, it was the obvious solution to their slag problems and a smart way of removing the residual material. Paul Legemaate, Materials Manager with responsibility for purchasing machines and issuing equipment: “It’s hard to believe but until last year, we had to remove slag manually. With an angle grinder and a chisel, two people were choking all day long. Obviously, you can easily conclude that an improvement was not an unnecessary luxury… but yes, you just have to find something on the market that offers the ideal solution. There were certainly options – we looked at a range of potential suppliers but the options they had available were all too elaborate and would have required too great an investment. Eighteen months ago, I visited the Technishow in Utrecht where I spotted a serious contender in the form of a Hammerhead 22 series prototype. I had a conversation with Timesavers from Goes. We already knew a little about the company, but it was the first time that we had seen a machine that met our very simple needs. They invited us to visit their demo centre in Goes.”

SLAG REMOVAL BECOMES SIMPLE

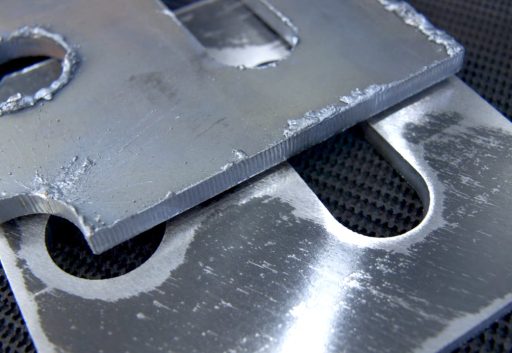

Peter de Regt, Area Sales Manager at Timesavers, and his colleague Oscar Salet explained that a morning of testing in the demo centre was all it took to convince them. De Regt: “The process is extremely simple and the machine has a modular structure. All Hanse Staalbouw was looking for was smart automation for the removal of steel slag. The Hammerhead does this by means of a shaft fitted with pins, which hammer off the slag. On one side of the machine you slide in the steel, on the other side it comes out clean. That’s all it is – but for Hanse Staalbouw, and many others since, it has provided unprecedented value.” The two of them are referring to the fact that practically no more fine dust is released. “Moreover, during the manual operations, there was always the risk of injuries due to hand-arm vibration syndrome (HAVS). This machine is not only fast, but also helps to reduce absence due to illness. It also facilitates getting around the shortage of suitable labour – young people no longer actually want to do dirty or risky work. That’s no longer something you have to worry about when cleaning off steel. It has become more accessible, more attractive and more mainstream. In fact, by having a machine like this as part of your processes, you’re actually working at being a good employer.”

LONG LIFE

De Regt estimates that the machine will last for a long time without experiencing any problems. Machines that work dry tend to run for longer. In fact, there are a large number of Timersaver machines in use that are now thirty years old. “The parts that you need at any given moment for replacement or maintenance purposes are always available.” Salet explains that the Hanse Staalbouw has become quite a representative reference for Timesavers. “In fact, I believe that with the introduction and success of the Hammerhead, we can now better connect with machinery manufacturers in the chain, such as Voortman Machines in Rijssen. Working together in the industry can really help to add value. We now have something that every industrial manufacturer is eagerly searching for. At Hanse Staalbouw, the process can be viewed as a success.” ‘Eagerly’ is certainly not an understatement – the company has sold more than twenty Hammerheads since its initial introduction at Hanse Staalbouw. Legemaate isn’t able to provide precise figures and percentages for the machine’s business benefits. “However, the positives are pretty clear – in the past, it took two men a whole day to remove the slag from our steel production.One man can now remove the same quantity of slag in just four hours, and he doesn’t need to do any manual work. Who wouldn’t want success like that? ”