Timesavers is more than ever ready for the factory of the future. A focus on minimising unnecessary energy consumption, yet maximising the simplicity, flexibility and connectivity of the machine. Here is what is new…

Safety and insight improvement

The front of the Timesavers Rotary Brush machine got a makeover. It is further designed to display the operational status: Standby, Eco Mode or Power Mode. The smart design includes a screen with live view of the machine’s exit. This is to ensure safer operations and reduce operator mistakes.

Upgraded Human Machine Interface

An HMI with new design and features is launched on the Timesavers deburring machines. The simplicity of the design, allows operators to work more easily. Now it is possible to store up to 500 different deburring programmes, which saves time in case of repetitive production. This ease of use and the adaptable programmes minimise the risk of mistakes. Rather it ensures consistency in high quality results.

Automatic Brush Setup System

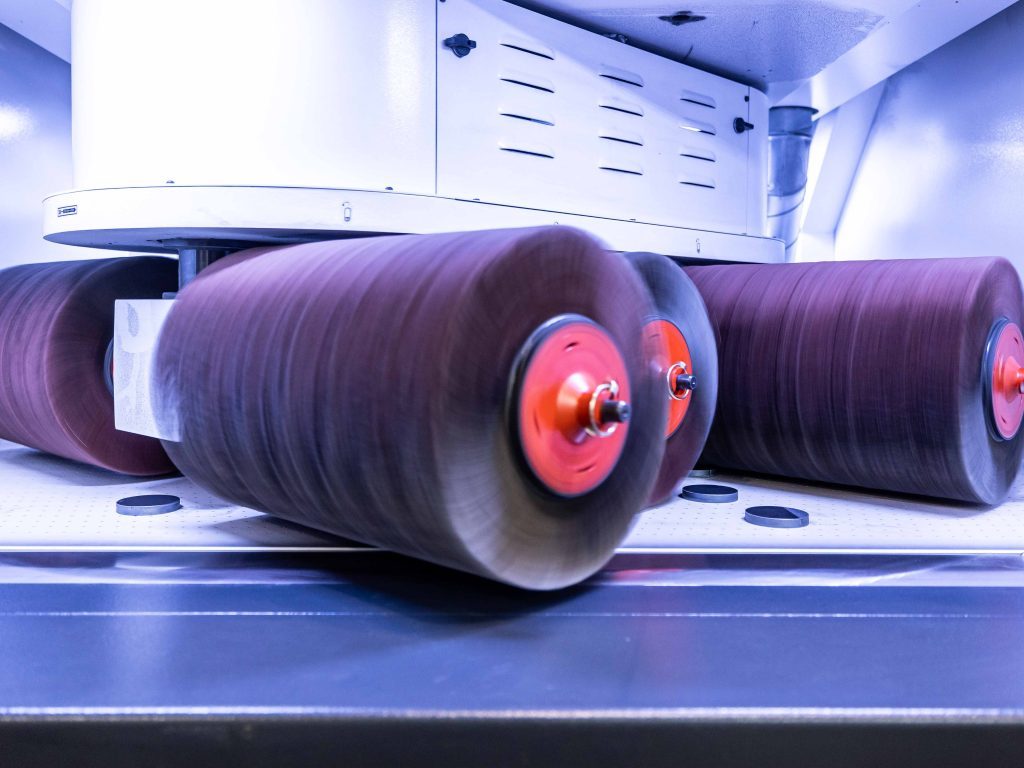

Increase the accuracy and repeatability of the deburring process with the newly developed Automatic Brush Setup System. This system fully automates the daily calibration process. It automatically compensates for process parameter changes, including tooling changes. All resulting in more consistent results, fewer operator errors and reduced tooling wear. Improved performance with reduced operator input, that’s performance and profit!

IoT and System Connectivity

The new version of the 42 RB series has the opportunity to connect with IXON. IXON offers remote control, Enterprise Resource Planning links and efficient data management. It is based on the latest Siemens controls platform and supports communication through the OPC-UA protocol. Moreover, you can connect your tools to the machine. Via the USB port you are able to integrate:

- A barcode/QR code scanner for easy setups.

- A thickness meter for accurate measurements.

- And even more new gadgets and tools…

ECO-mode

Save up to 30% of energy when working in the ECO-Mode. This mode is of course designed to make the machine more eco-friendly. The machine gradually starts up to save energy. By optimising the motor and systemic parameters, it will reduce the machine’s energy consumption during production. As a result, the overall wear of the machine and tooling, heat generation and noise will be reduced. Last but not least, the ECO-Mode provides a calmer work setting.

Power Mode – Maximal Grinding power

Is there a challenging grinding task? Set the machine to Power Mode for maximum grinding performance. With more power and speed you can be assured that it will take care of deburring, extreme edge rounding and finishing of the parts.

Standby – No unnecessary power consumption

Whenever the machine is not in use in between processing, it can be set in Standby. The machine’s core functions and the dust extraction halt to reduce energy waste. Such as the motor operations, the conveyor belt and the abrasive belt movements. To continue again with the deburring process, it takes one button to quickly start the machine again. It is perfect for avoiding unnecessary power consumption.

Power meter – Energy use history

Live energy data will encourage operators to change the settings to the optimal parameters. Gain insight into the data history from the Power Meter. It can be helpful for researching energy use patterns. Predict future energy needs, start with energy saving steps and save costs.

|

|