Timesavers RB series offer an advanced solution for mechanical deburring / edge rounding / laser oxide removal / finishing. In order to get the right machine that fits your product range, it is important to know the machine’s capabilities.

Deburr and finish various types of sheet metal

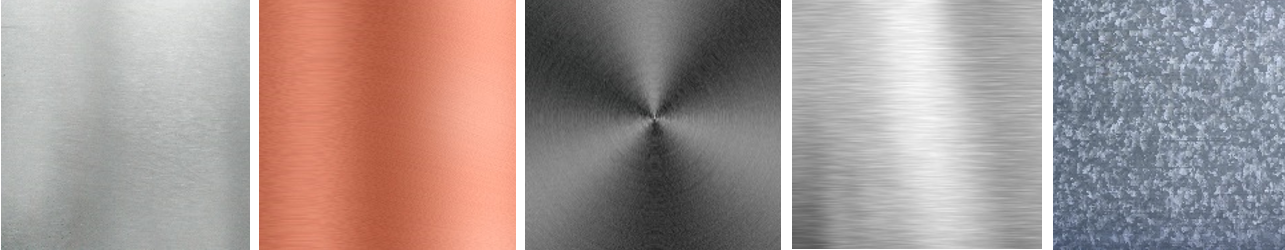

Most common metals that get processed in the machines are mild steel, stainless steel and/or aluminium. However, the machines of Timesavers are also able to process metals such as copper or zinc coated products. Not to mention, it can deburr Zintec, galvanized and plated material as well. Different metals, even some highly flammable ones, can be processed thanks to a wet extraction unit. When only steel is being processed, it is an option to use a dry dust extractor, which needs lesser maintenance. Moreover, the machine starts a cleaning cycle every 4 hours to keep the machine in good state.

Note: Most customers who process various metals, use multiple sets of brushes to avoid cross contamination.

Process product of different dimensions

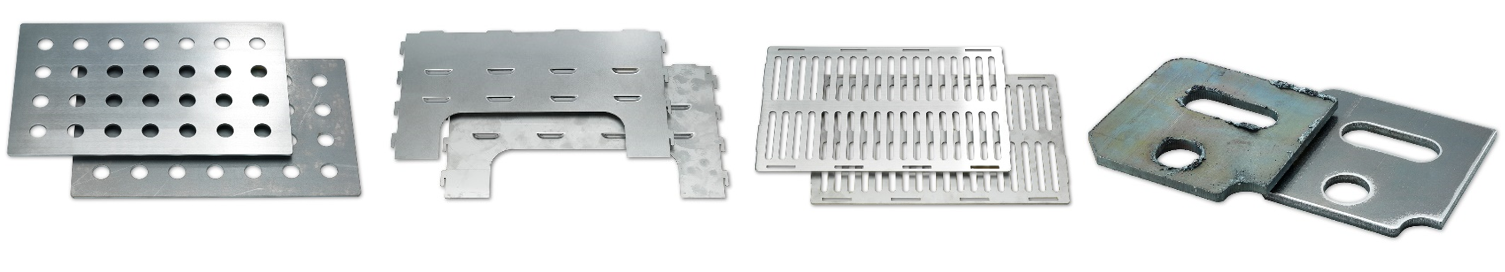

The table opening of the RB series is 0-100 mm and the table and heads can easily be adjusted according to the thickness of a product. This makes it possible to run different thicknesses of sheet metal through the machine of which the parts can be flat, formed or 3D, with pockets or protrusions.

There are three RB machines with different widths. The 22 RB series is ideally for small parts up to 600 mm width. The 32 RB series is suitable for parts with a width of up to 1100 mm. The 42 RB series is the largest machine that can process small and large parts of up to 1600 mm. It can be difficult to decide on the width of the machine. Therefore, it is recommended to choose a width that can process one of the largest products from your product range.

Process product of different thicknesses

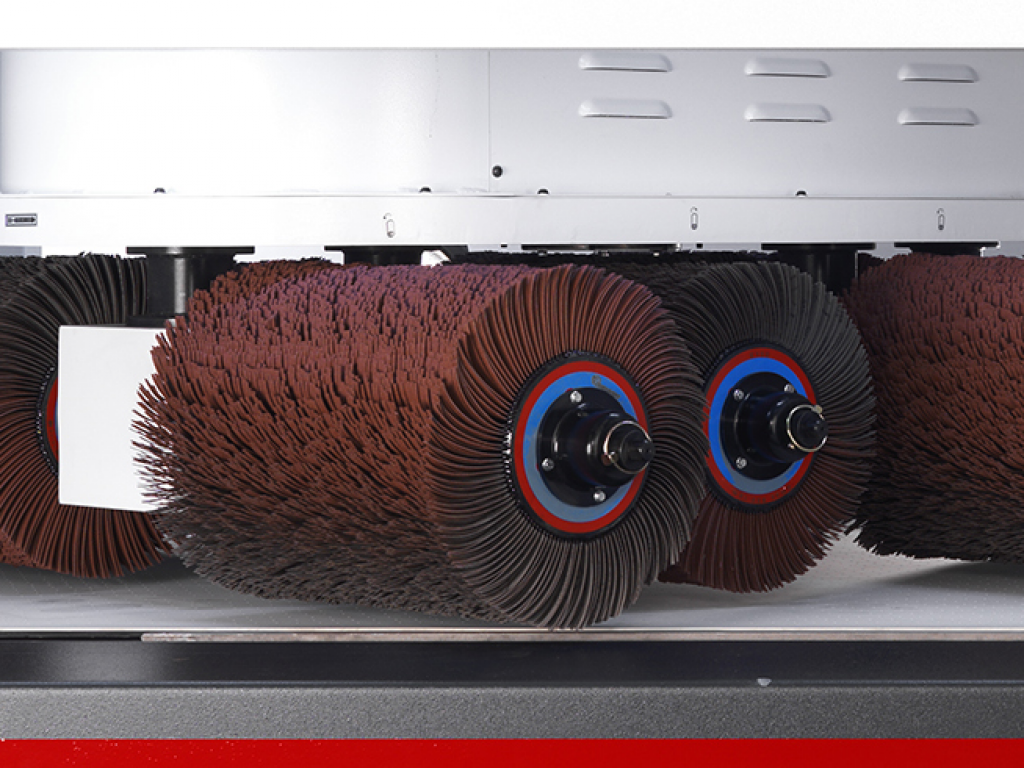

With the rotary brushes it is possible to process different thicknesses of material at the same time. This applies to the 22 RB series as well as the 32 RB series and the 42 RB series. This is because the deburring brushes are flexible and the flaps of the brushes can easily reach all spots. However, we recommend processing products with a thickness difference of no more than 5 mm. The big advantage of this is that you don’t have to reset the machine every time you want to work on different thickness of sheet metal. This speeds up the production process and allows you to work on sheet metals of different thicknesses. However, it is important that the products are made of the same material if you want to machine them together.

Deburring machine for small and large products

It is often questioned what sizes can be processed through the machines. The largest possible width of Timesavers deburring machine is 1600 mm, but that does not mean it can only process large products. On the contrary, smaller products of up to 50 x 50 mm can be kept in place by the sticky conveyor belt, the vacuum table or magnetic strip on the table. This enables a flexible production of sheet metal parts.

The most versatile deburring machine

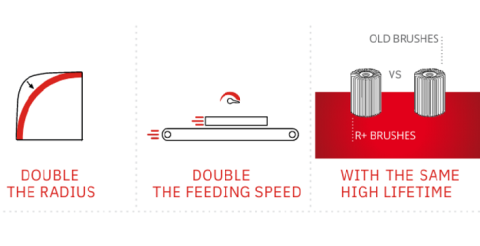

R+ brushes

By using the R+ brushes for the 32 RB series (manufactured after July 2021) and 42 RB series, you will increase your productivity. These brushes are designed with more abrasive, allowing them to remove more material in less time. Ideal for making a radius and achieving a faster throughput of sheet metal parts. And that while the service life is the same as the old brushes. Ultimately, using the R+ brushes help reduce production costs.

Universal deburring machines

The deburring machines from Timesavers are universal, because they can process any metal product with a size up to 1600 mm. The desired applications can all be added in one machine, so that the products are finished in one pass.

Deburring – Products from different metals and sizes can all be deburred by our RB series.

Edge rounding – The edges can be rounded, even up to a radius of 2 mm with the 42 series.

Laser oxide removal – Laser oxide can be removed by our RB series.

Heavy slag removal – Heavy dross can be removed with the use of the hammerhead, only applicable on the 42 RB series.

Finishing – All Timesavers machines, including the RB series, are capable of applying a beautiful finish.

Are you still wondering whether the RB series is suitable for your product range? Please contact us for advice or if you need extra information.