Stainless steel is a widely used material due to its excellent corrosion resistance, strength, and aesthetic appeal. It is commonly used in various industries such as automotive, aerospace, medical and construction. Read below more about why deburring stainless steel is important, what things you need to consider when deburring, how to remove the burr and what machines can be useful.

Why deburr stainless steel?

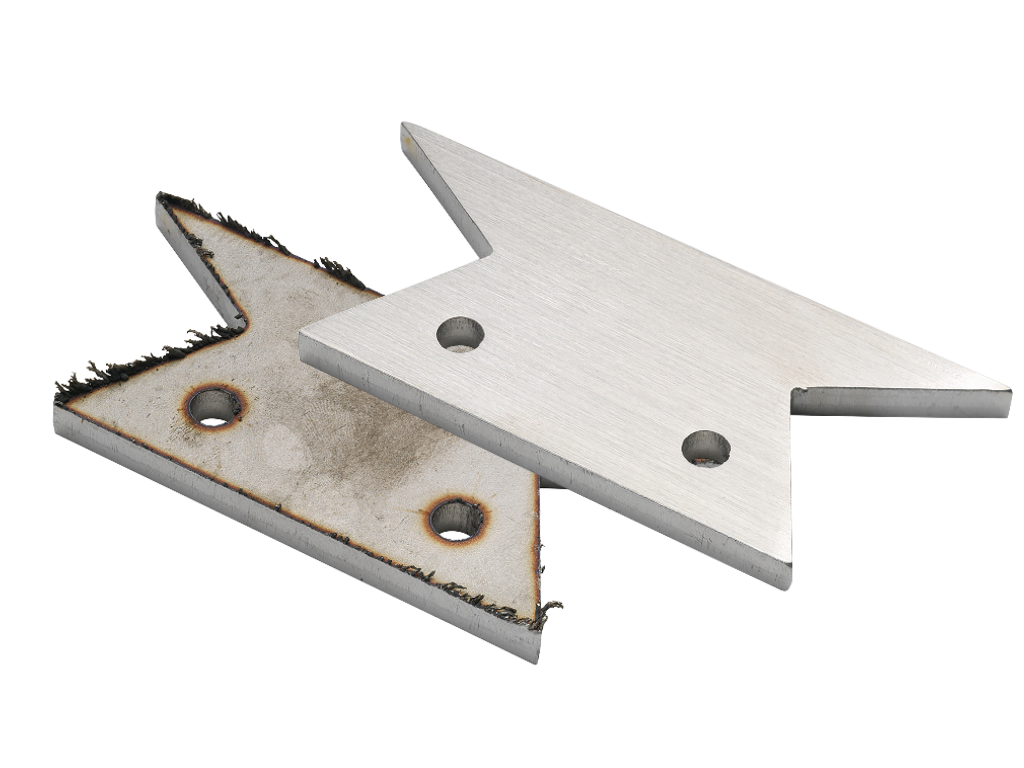

During the fabrication process of stainless steel products, burrs and sharp edges can be formed due to cutting, stamping, punching and so on. These burrs not only affect the appearance of the product but also pose a safety hazard to workers and end-users. Therefore, deburring, which is the process of removing these burrs and irregularities, is essential to ensure the quality and safety of the product.

The right machine for processing stainless steel

Burrs can vary in size, shape, and locations on the stainless steel surface. This affects the choice of a machine configuration. Sometimes it is necessary to use an extra abrasive belt for pre-grinding large stainless steel burrs.

A Timesavers machine is an all-in-one solution that can carry out multiple applications in one pass. Only deburring does not remove sharp edges. You will need a top brush to break the edges, or a rotary brush to get a nice radius. A non-directional finish or Scotch Brite finish is an option and can be accomplished with a contact roller at the end of the machine.

This desired surface finish of the stainless steel product is important to keep in mind. It is decisive for the type of machine execution and type of grinding material. A wet working machine applies a shinier finish compared to the dull finish of a dry working machine. Would you opt for a wet or dry working machine? And what Ra value is the standard for your product batch? With more than 70 years of knowledge within the field, we can help you find the perfect solution.

Advice: Decide on what applications and results you need in addition to deburring. It will determine what machine fits your needs. Contact Timesavers for custom advice.

Knowledge base

Knowledge base

Would you like more information on surface roughness or creating a radius? Have a look at our articles in the knowledge base.

Tooling for your grade of stainless steel

The abrasive belt is a great tool for deburring and smoothing out burrs of stainless steel. These belts consist of an abrasive material coated onto a flexible backing, and they are available in different grits. The material determines what kind of grit is most suitable. The coarser the grit, the more aggressive it is. And thus it should only be used for tough materials. The abrasive belt is recommended to be used in combination with the rotary brushes from Timesavers. This combination makes sure to remove all burrs and round all edges.

It is common to deburr stainless steel with Aluminium Oxide belts. However, different grades of stainless steel have varying properties. Think about hardness and ductility, which affect the deburring process. This requires choosing the right grit. For instance, authentic stainless steel such as grade 304 is softer. Martensitic stainless steel on the other side, such as grade 440C, is harder and more challenging to deburr.

Advice: An Aluminium Oxide belt is excellent to deburr your stainless steel. In case of large burrs, we recommend deburring with an extra machine head for a second abrasive belt. For advice on choosing a grit, you can contact us anytime!

For all your questions

For all your questions

Are you curious about the tooling that is available for Timesavers machinery? Or would you like to know what belts or brushes to use for your application?

Ask your questions! Our team will gladly advice you and help you further.

Pressure and speed

When deburring stainless steel, you need to apply the right amount of pressure. Therefore, it is important to test the pressure on a sample. When the edges at the front side of the part are grinded off, it is a sign to lower the pressure. Of course, it is only the surface that needs to be deburred by the abrasive belt.

The speed of the grinding and transport belt should be carefully set. Grinding causes friction and friction causes heat. For this reason, grinding stainless steel at a slow transport speed, means longer friction and more heat. To avoid the deformation of parts, it is recommended to set a higher feeding speed.

Advice: Carefully choose the amount of pressure before processing all your parts. Also, make sure the friction caused by the speed does not generate heat. Timesavers machines have a frequency control and make it easy to quickly adjust speed.

Safety during the deburring process

The stainless steel deburring process can generate sharp metal fragments and dust. This poses a safety hazard to coworkers. The solution? A unit that extracts all dust and residue from the machine. That is why Timesavers partnered with Absaugwerk. Absaugwerk produces powerful dust extractors. The units thoroughly clean the air after which it is led back into the hall or outside. This allows deburring machines to last longer, keeps the workplace clean and employees safe.

Advice: Equip your Timesavers machine with the dust extractor from our partner Absaugwerk. Find the customer testimonial on the page about high quality extraction solutions.

Our partnership with Absaugwerk GmbH

Our partnership with Absaugwerk GmbH

Absaugwerk is supplier for extraction solutions at Timesavers. The B series range consists of high-quality extraction solutions for the protection of people, machines and the environment in the manufacturing industries.

Stainless steel deburring machine

A deburring machine from Timesavers International is a popular choice for manufactures. Manufacturers look for ways to make the deburring process faster and more efficient. What better way to optimise than letting a machine do all the work? Machines offer numerous advantages over manual deburring processes. First of all, you only need one machine operator. Excellent in times of labour shortage. Moreover, the results become consistent, not depending on a worker’s set of skills.

One of the main advantages of using a deburring machine is the increase of productivity. A machine can remove burrs form large volumes of stainless steel parts quickly and consistently. At higher speed not to mention. The automated nature of the machine also means that it can operate continuously without the need for frequent breaks or manual adjustments. It just cannot get tired.

In addition, a deburring machine can improve the quality of the deburring process. Timesavers machines use advanced grinding technologies involving abrasive belts and rotary brushes. Both to remove burrs and other surface imperfections from the stainless steel surface. These tools can be customised to suit the specific needs of the application. The machines can be used for deburring stainless steel, but also steel deburring, aluminium deburring or any other type of sheet metal deburring. And if you would like to combine deburring and finishing, that is no problem. All can be taken care of in one machine.

Overview of Timesavers machinery

Overview of Timesavers machinery

From entry-level deburring machines to large rotary brush machines for edge rounding. From small finishing machines to coil-to-coil finishing lines. The options are limitless.