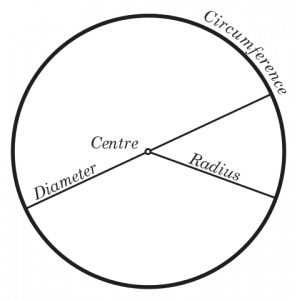

Sheet metal has sharp edges and corners after cutting and therefore it is necessary to round the edges by hand or by machine. For some sheet metal products it may be a requirement to achieve a certain radius on the edge of the material. A radius can be measured as a straight line from the centre to the circumference of a circle of sphere, as shown on this image:

How can a radius be measured?

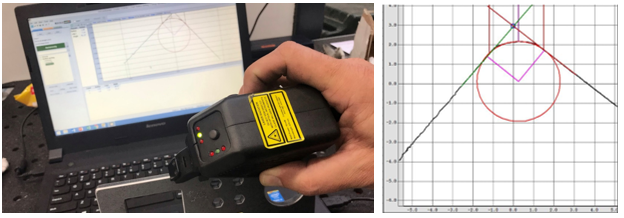

By a high end laser scanner and special computer software, edge radius is determined. When the tool is held to the materials’ edge the radius calculation program calculates the radius by determining half the length of its diameter.

What are the advantages of corners with a uniform radius?

- Products with rounded corners and edges are safer during handling and result in less injuries of assembly workers or end users.

- Preferable for environments with hygiene requirements, especially in pharmaceutical or food processing industries, because a radius prevents the bacteria and microbes to be stuck at the edges or in ridges.

- A radius is crucial for the quality of surface treatments such as coating or painting.

- For galvanizing metal products, the edges need to be rounded to a radius of a minimum of 1 mm.

Although a radius of 0.3 mm to 0.5 mm suffice for most companies, it is sometimes required to achieve a radius of up to 2 mm especially for products that need to be coated. As seen on the measurement above, the deburring machine from Timesavers is able to achieve a 2 mm radius on steel and the processing speed depends on the dimensions of the material.

|

|

|

Why is a radius needed for coating?

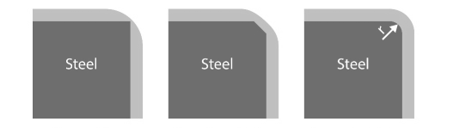

A metal product with a radius on all edges ensures the quality of coating. The paint layer will be uniform on the metal product and therefore it will be harder for the paint to peel off and eventually rust, compared to sharp edges, where there is little to no paint that sticks on the edge.

When the edge is slightly rounded, the paint layer will cover the corners, but it is not equal to the layer of the surface and sides. For this reason it is desired to obtain a radius of 2 mm. It results in a uniform coating that completely adheres to all sides of the sheet metal part.

Timesavers ultimate machine for a radius of 2 mm

The 42 RB series from Timesavers is the ultimate solution to achieve a radius of 2 mm on steel, stainless steel, aluminium and more materials. When the speed of the eight rotary brushes and the conveyor belt is set right, the products will be rounded to a R2 in one pass. The parts will have uniform rounded corners. Making the radius can be done in combination with deburring and finishing as well. Find out all of the possibilities of the versatile 42 RB series machine.

Please do not hesitate to contact our sales department for more information.

About rounding edges

+

Why round the edges of metal?

First, for safety. Metal is very sharp and it could cause injuries to employees during handling and assembly when the edges and corners are not rounded. Another reason is the quality of painting. Paint adheres much better to a rounded edge and prevents the coating from peeling off.

+

Why do you need an edge rounding machine?

Manually rounding the edges of metal is a time-consuming work and requires skill in order to get consistent quality. However, an edge rounding machine is able to process multiple parts at once with consistent edge rounding quality at much higher speed.

+

How to round the edges of metal parts?

You can round the edges manually by using abrasive grinding paper, but for better results it is recommended to round edges mechanically. Abrasive rotary brushes are an excellent solution to create a consistent radius on your parts. Discs are used if only a slight edge break is needed.

+

How do you get a uniform radius?

A rotary brush can grind the edges of any metal part to a uniform radius. The brush flaps with abrasive material are flexible and only hit all the edges when it rotates, while leaving the surface unharmed.

+

How to create a 2 mm radius?

The more often the abrasive brushes come across the metal part, the bigger the radius. The speed of the transport belt and rotary brushes needs to be set correctly to achieve a 2 mm radius.

+

How do you measure a radius?

The best tool to measure a radius is a laser scanner. It comes with a program that shows the exact radius and can provide a drawing of the rounding.