Copper is famous for its excellent electrical and thermal conductivity. However, sheet copper is regularly used as a construction material for architecture and design. Just like any other sheet metal that has gone through the laser cutter, the copper parts are left with burrs. As world-leading specialist in this field for over 80 years, let us explain: What are things you need to consider when grinding copper.

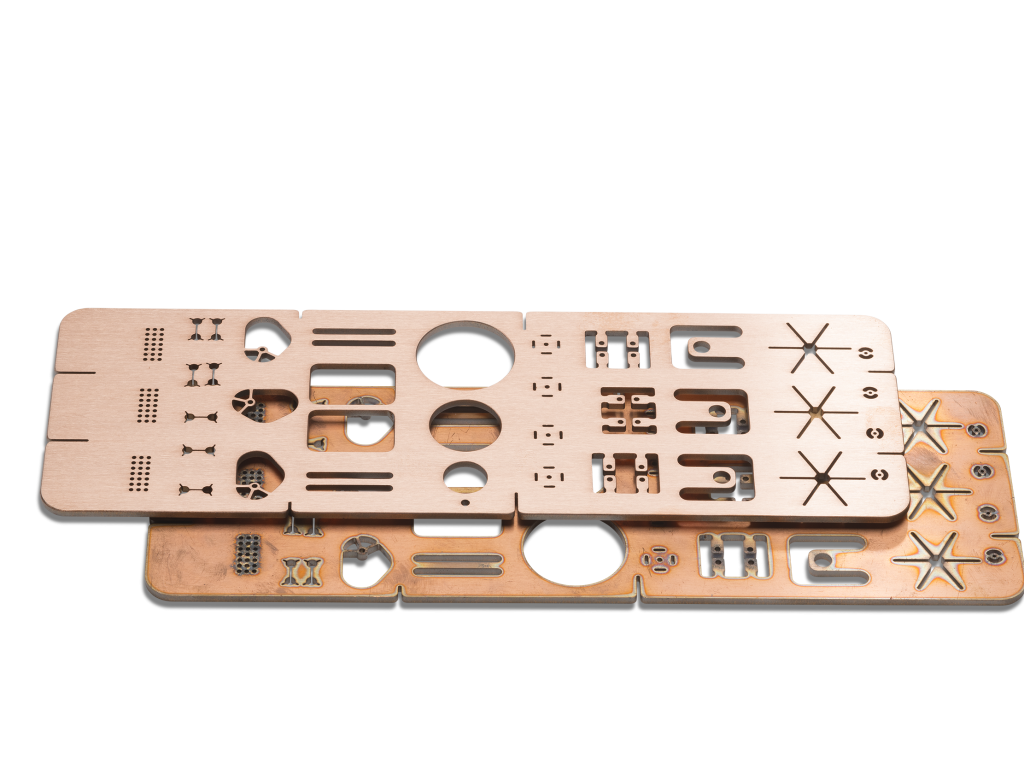

Cutting process of copper sheets

Copper can be cut by several cutting technologies, such as plasma, laser and water-jet. The burrs that are formed around the edges of the surface are sharp and unaesthetic. To prevent any injuries to personnel during handling and to improve the functionality as well as appearance of the product, it is recommended to deburr the copper parts. A crucial step to ensure the quality.

The right deburring tool for copper

Every Timesavers machine is suited for at least the standard metals like copper, steel, stainless steel and aluminium. Each has their own working width, so please keep the dimensions of your products in mind. Does your production involve small copper parts? You may opt for a smaller, entry-level machine. In case you have large copper sheets, it is possible to get a larger machine.

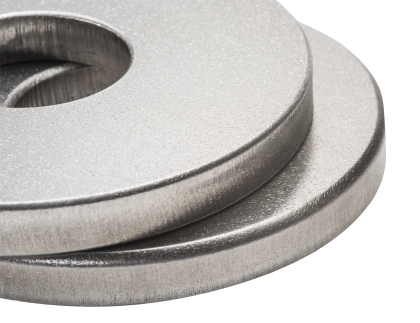

When deburring copper sheet, you remove the burr and at the same time you grind the irregularities off surface. The product is then left with a smooth surface, yet sharp edges. That is when the rotary brush comes in to play. The RB-technology is the ultimate innovation for rounding the corners to a certain radius.

Advice: Decide what treatment the copper needs and in light of the product dimensions, you can choose your very own Timesavers copper deburring machine. Make use of our free online decision aid.

Achieving a radius on sheet metal

Achieving a radius on sheet metal

Edge rounding up to a radius of 2 mm? That is possible with Timesavers RB-technology. Read our knowledge base article about the importance of creating a radius.

Tooling for deburring copper sheets

The abrasive that can be used for copper is the material aluminium oxide or silicon carbide. The latter has pointy grains that cut easily through the metal. The reason that silicon carbide is preferred over aluminium oxide is because the results look better aesthetically.

Non-woven belts are made for finishing of metal in general. This is often the last step in the deburring process. Among the metals that can be treated with this type of belt is copper too. If you desire a particular finish or surface roughness, contact us for more information.

Advice: When grinding copper, you can achieve the best results with use of a silicon carbide belt.

Pressure and speed

Just like aluminium is copper a soft material. This means that there is not much pressure needed to remove burrs. Too much pressure will leave deep scratches in the surface, so be careful. And as you probably know, copper is conductive. That is why the parts and sheets get heated quite fast. The solution to the generation of heat is either just speeding up the transport, or slowing down the speed of transport and grinding belt.

Advice: Try out on a sample which pressure and speed to use for satisfying end-results.

What about the dust

Exposure to copper dust can be harmful for people, property and the condition of the overall workplace. Not to mention that metal dust is combustible. One sort of metal dust more than the other, but it all comes down to one advice: Get that powerful dust extractor. It is with good reason that Timesavers International partnered up with Absaugwerk GmbH to ensure all customers of a safe production process.

Advice: Opt for a wet extraction unit that filters the metal dust out of the air. The fresh air will be transported back into the hall or outside.

Our partnership with Absaugwerk GMBH

Our partnership with Absaugwerk GMBH

Absaugwerk is supplier for extraction solutions at Timesavers. The B series range consists of high-quality extraction solutions for the protection of people, machines and the environment in the manufacturing industries.

Deburring machine for copper

Every machine of Timesavers is able to process copper. From deburring to edge rounding and finishing. The choice of machine is depending on the size of your products, the results you want to achieve and the budget you have available. Our Timesavers experts are ready to listen to your application problem. They will help you find the perfect copper deburring solution.

For all your questions

For all your questions

Are you curious about the tooling that is available for Timesavers machinery? Or would you like to know what belts or brushes to use for your application?

Ask your questions! Our team will gladly advice you and help you further.