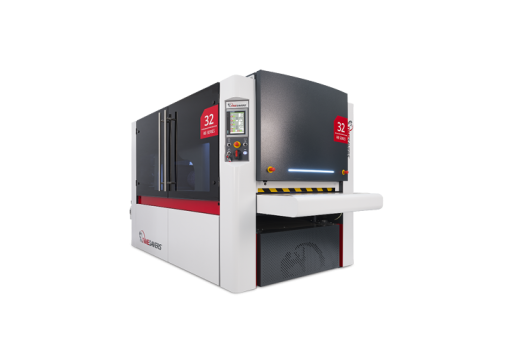

Timesavers has recently added to the available configurations of the 32 RB series with the addition of the HWRB, also featured at last year’s EuroBLECH.

Dross removal with Timesavers’ new 32 RB series

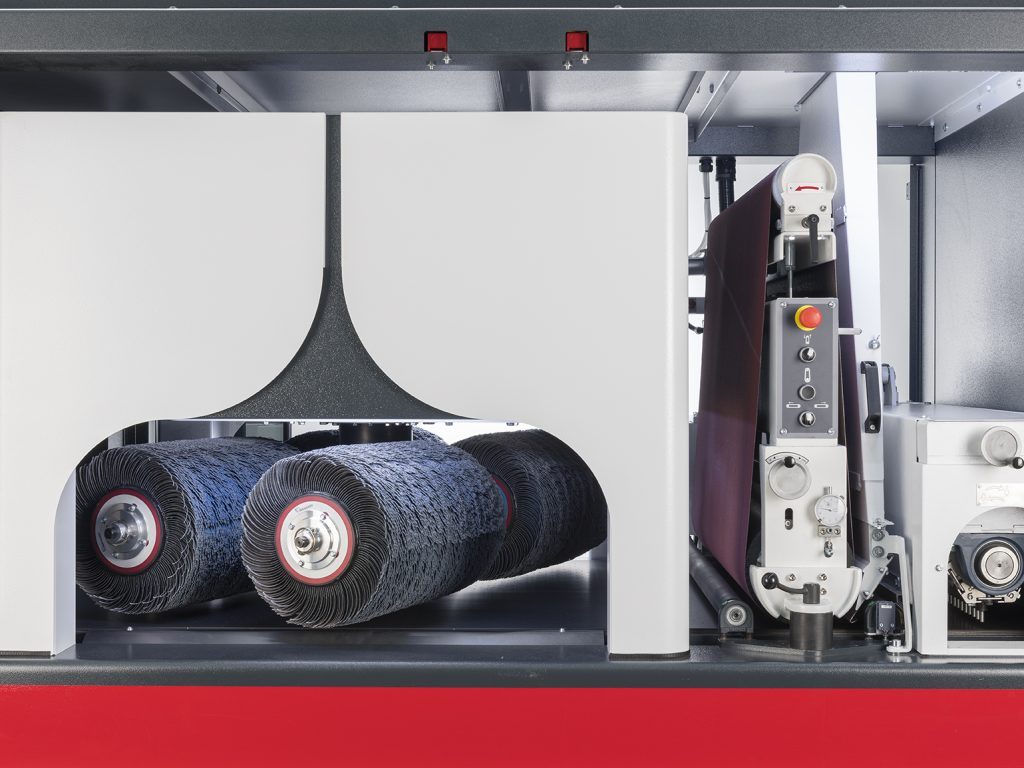

The hammerhead technology is designed by Timesavers for efficient slag removal, and was until recently only available on the 10 series entry level model, 22 series and large 42 rotary brush machine. Now that Timesavers has introduced the new 32 series HWRB, it has become the compact solution for slag removal, deburring, edge rounding and laser oxide removal.

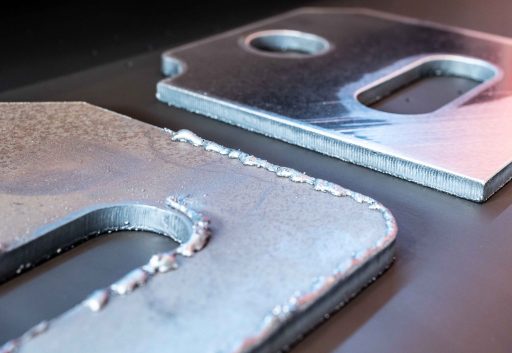

A common problem that occurs during plasma cutting, is the formation of large burrs. Also known as slag or dross. This slag can be removed within no-time thanks to the hammerhead solution. This application is followed by deburring and rounding of edges up to a radius of 2 mm in one pass. No wonder that the machine is so popular!

One may think that the 1100 mm working width is solely for large products. However, the machine can be equipped with a strong magnetic track that can hold small steel parts of 50 x 50 mm in place.

Once in a while, the worn tooling needs to be replaced. Thanks to our quick-change system, the machine is quickly made ready for use again. In order to double the lifespan of the pins, Timesavers developed a module system that enables the operator to easily turn or change a module with worn hammer pins.

|

|