The recent arrival of an 81 series wide belt precision grinding machine at metal polishing and finishing specialist Van Geenen has had an immediate impact. Through improved capacity, productivity and overall capability the Rijssen, Netherlands-based company is opening up new business opportunities.

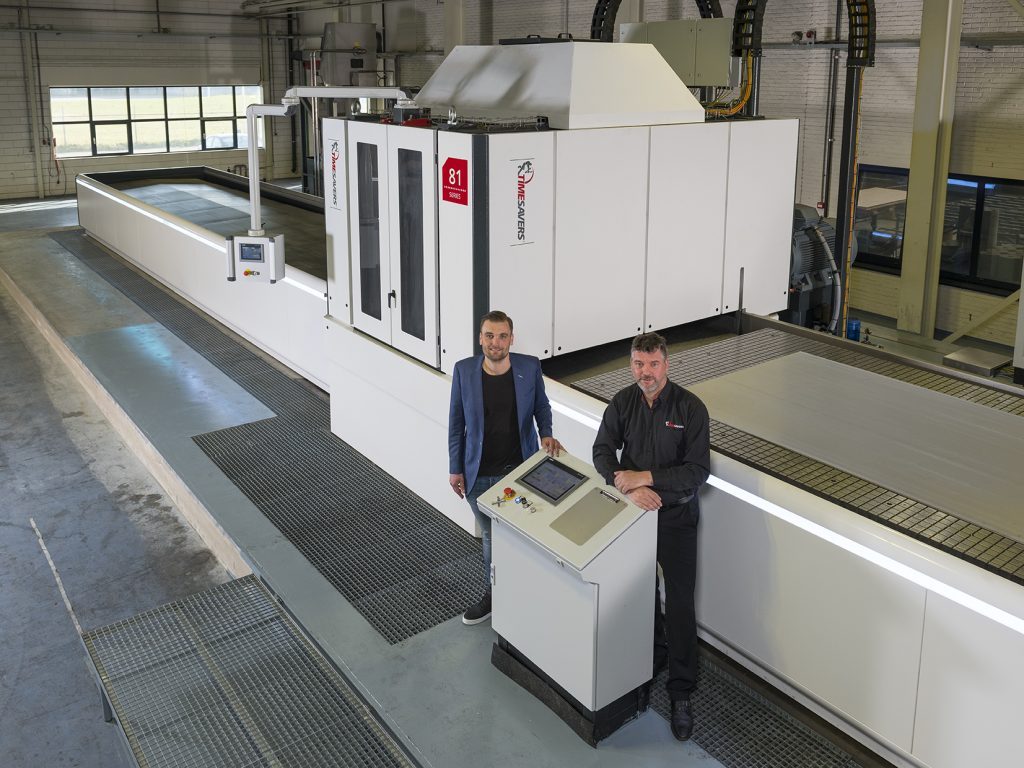

For a business that began back in 1977 when Arnold van Geenen and his sons Nico and Gerrit joined forces to provide a hand polishing service, with the founders having to sell their cars to buy the vital tools required to get started. Van Geenen B.V. Metaalfinishing is unrecognizable, now under the guidance of Nico’s son Bart van Geenen the company operates from 5000m2 premises, housing the latest in polishing and grinding technology. The most recent arrival being the investment in the Timesavers 81 Series grinding machine, which places the business firmly in the 21st century.

From those early days the company began to specialize, particularly on stainless steel and other exotic materials. The emphasis is firmly on producing sheet and tube material to the highest quality in terms of surface finish (right up to Mirror 8 grade), with greater efficiency and consistent technical quality of products. “Hand polishing remains a critical part of our business, but automation has been central to our development since our first investment in a Grindingmaster/Timesavers back in 1984. We are always looking to improve efficiency and our investment in automation has boosted productivity,” says Managing Director, Bart van Geenen. “As such, our partnership with Timesavers continues with this major investment in the 81 Series machine, an investment that driven both by the heart, with my father’s desire for manufacturing technology, and head, with me focused on the commercial potential.”

Quality and relationships

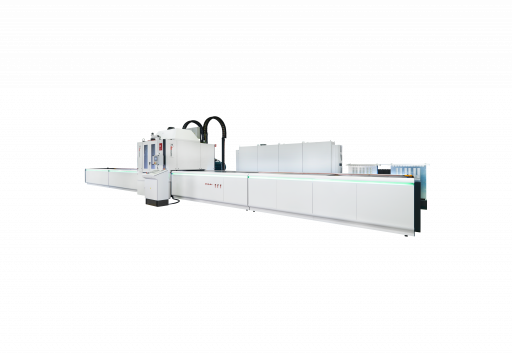

Van Geenen prides itself on the quality of its work and the strength of its relationships with customers, this combination has opened up new business opportunities for its polished sheet and tube products across markets including architectural, tanks, and food processing. “We have always had the ability to do things that our competitors can’t do and to continue that we recognized it was time to move into precision grinding.” The scale of the 81 series will also future proof production at Van Geenen, at an overall length of 25 meters the machine has a capacity to grind sheet or plate from 0.15 mm up to 100 mm; with stock removal rates of up to 0.2 mm/pass achievable with a table size of 2.1 m by 8.5 m to an accuracy of 0.02 mm and 0.3Ra and less.

The 81 Series is already delivering significant time savings for van Geenen compared with existing processes. For example, producing a 4m long 2 m wide by 20 mm thick sheet for a customer in the food processing industry, which required a 0.8Ra surface finish used to take between 4-5 hours to complete, this is now achieved in one hour on the 81 series. “With the level of investment in the Timesavers 81 series our hourly rate has increased, but this is justified as our throughput is much greater and lead times much shorter and that level of efficiency is vital when putting forward proposals to customers. We are also aware that none of our competitors in Europe have this capability,” says Bart van Geenen.

Precision grinding vs Milling

Encouraging for van Geenen has been the enthusiasm from customers for the use of this wide belt grinding technology with the Timesavers 81 Series. The efficiency of the system allows it to replace milling as an operation, reducing the number of processes and improving efficiency. With milling at least two set-ups may be required for roughing and finishing, whereas with the 81 Series just one operation takes the part to the finished state. This is particularly important on stainless steel parts where the clamping of the material for milling can induce stress in the part. Using the vacuum table of the 81 series eliminates this completely, while achieving improved results in terms of flatness and surface finish.

“The 81 Series is a genuine alternative to conventional processes and, it is my role to convince customers that the process is viable and meets their requirements. Thankfully, customers are open to innovation and are willing to listen and try new processes,” says Bart van Geenen. “I recently quoted a customer for some polished titanium plate, within five minutes of delivering the quote I received the order!”

Partnership and collaboration with Timesavers

The development of the Timesavers 81 Series came about following conversations with suppliers of sheet material, particularly Titanium and other exotics such Zirconium and Molybdenum, who were facing challenges processing, accurately and efficiently these materials. The result is a wide belt reciprocating table abrasive machine that eliminates problems found when milling or grinding using stones or abrasive wheel technology. In collaboration with abrasive belt manufacturers Hermes and 3M the 81 series can process materials much more efficiently, in some cases such as grinding Molybdenum a conventional cycle time of 10 hours was cut to 25 minutes!

A typical Timesavers 81 Series cycle consists of a fast rough grinding cycle followed by up to three spark-out passes, with the sheet, which is positioned on the powerful vacuum table, then rotated and the cycle repeated on the opposite face. The result is a thickness accuracy across the entire sheet of 0.25 μm with the major benefit of the process creating a ‘short-scratch’ finish.

Timesavers and Van Geenen are also collaborating with this new investment with Timesavers introducing potential customers, who may not be in a position justify the purchase of an 81 Series just yet to Van Geenen, and the machine being made available to Timesavers as a real-world example for customers to see the potential of this grinding technology. “This investment is backed by our experience of the service provided by Timesavers over many years to our company and both our companies will continue to grow alongside each other as a result of that relationship.” Concludes Bart van Geenen.