1939

The founding of Linden Machines

The origins of Timesavers date back to 1939, when Arie van der Linden started a repair shop for woodworking machinery in Rotterdam. The company was located there in Rotterdam-Zuid on the Wolphaartsbocht.

1953

Stroke and drum sanders

The company also started specialising in stroke sander and drum sander machinery.

1963

First wide belt sanders

In this year the company had added wide belt sanders to the range of abrasive equipment.

1965

Company moves to Goes

After the bombing of Rotterdam, the company used industrial subsidies to move to Goes. They ended up in a new business district, right on the south side of the train tracks. This location offered much more expansion opportunities compared to the old location on Wolphaartsbocht, which was in the middle of a large residential area.

1967

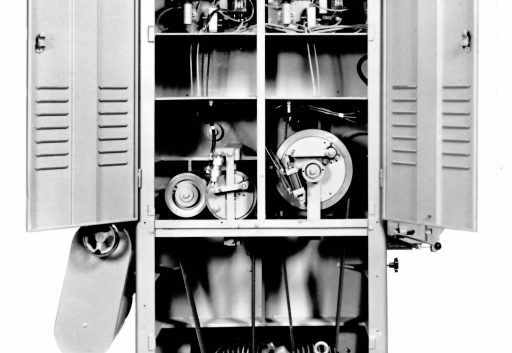

Variety of sanding machines

The sanding machines became available in multiple executions, such as the CSB/CSB 2, SCSB/SCSB 2, CSO of which many are still available on the second-hand market.

1970

Grindingmaster

From the 1970s the company started building not only wood working, but also metal working machines for steel, aluminium, copper and stainless steel. These were introduced as the Grindingmaster.

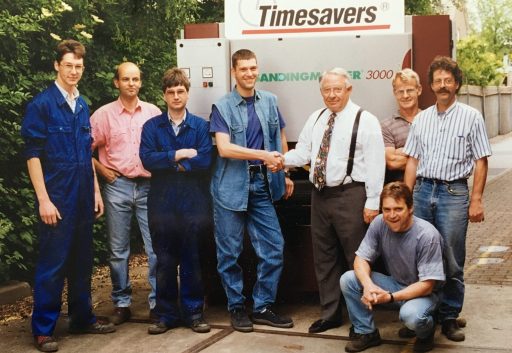

1996

Takeover of Linden Machines by Timesavers

Twenty five years later, the company was taken over. This was the start of Timesavers International B.V. in 1996. Since then, the organization has been responsible for managing all of Timesavers' global operations, with the exception of those in North America. The company had now become the world market leader in wide-belt sanding and grinding machines for wood and metal applications.

1999

Grindingmaster 3000 & 4000

The Grindingmaster 3000 and 4000 were modern and innovative machines for the time. Besides being functional, the engineers also paid attention to the appearance of the machine. Due to the power of the machine, it was decided to go with a variable-frequency speed drive. The machines were also advanced with photocells and were widely sold.

2000

Focus on metal

Up till 2000 Timesavers was equally involved in wood and metals. Hereafter, the decision was made to concentrate more on metals. In Europe more than 90% of the company’s current business came from the metal industry.

2003

Introduction of the first wet working grinding lines for coils

To cater to the growing demand for tailored solutions, the company introduced wet working grinding lines. A machine that diminished the risk of explosions and deformation of parts. Additionally, it can process a mixture of materials safely, without the need for an extensive cleaning process or a dust collection unit.

2005

Introduction of the first precision grinding machine

From this year on, it became possible to grind metals with a precision of no less than 0,02 mm. The precision grinding machine, the 81 series, uses wide grinding belts with a tight tolerance to process titanium, molybdenum, stainless steel, aluminium/nickel alloys, carbon steel and more.

2009

Introduction of the rotary brush machines

The rotary brush technique is designed for edge rounding up to a radius of 2 mm and finishing of a wide range of materials. Moba was one of the first to have this deburring and edge rounding machine.

It’s such a durable machine, even though it runs eight hours a day. As far as I’m concerned, it’s the nicest machine I’ve had up to now.

2014

Introduction of a top-and-bottom machine

In addition to a top grinding variant, Timesavers had also developed a bottom grinding variant for finishing cold and hot rolled plates. It is suitable for use in coil-to-coil lines.

2014

A new design of the 42 RB series

Together with a design agency, we created a new design for the 42 RB series. The design makes our corporate identity stand out even more.

2015

First Titanium calibration project in China and the USA

In 2015, a party was organised to celebrate cooperation with some major corporate customers from the US and China. The projects involved the 81 series precision grinder. Excellent for grinding steel, titanium, aluminium, and other exotic metals.

2015

Introduction of the manual grinder

The 10 series is Timesavers’ versatile starter model for manual deburring, edge rounding and finishing of metal. This machine has two heads that can be fitted with various types of tooling. Tooling includes different types of pads and brushes for deburring, edge rounding, finishing, laser oxide removal and heavy slag removal.

2016

Winner of the Red Dot Design Award

Especially because of the advance in technology Timesavers had been able to develop a new leading deburring process, the rotary brush machine. In 2016, the company won the Red Dot industrial design award for the 42 RB series.

2017

Introduction of the 32 RB series

In addition to the 42 RB series, the 32 RB series is introduced. This machine is slightly smaller with a working width of 1100 mm. It offers an ideal solution for deburring, edge rounding, laser oxide removal and finishing. Operating this machine is intuitive and effortless.

2018

Establishment of China headquarters

A celebratory opening in China as the Chinese headquarter was established. Our managing director, Paul Hartendorp, was there to hand out some presents.

2019

Introduction of the hammerhead

Slag removal with a chipper or angle grinder is a thing of the past. The Hammerhead takes care of heavy slag and large burrs. The pins of hammer the dross off the parts by a counter-clockwise motion. Hanse Staalbouw was the first company in the world to commission the 22 series machine equipped with a Hammerhead unit.

One man can now remove the same quantity of slag in just four hours, and he doesn’t need to do any manual work. Who wouldn’t want success like that?

2020

Introduction of the 22 RB series

The 22 RB series is an even more compact version of the rotary brush machines with its working width of 600 mm. This machine is suitable for deburring, edge rounding, finishing and laser oxide removal. Ideal for companies that mainly want to process smaller parts in an efficient and timesaving way.

2021

Partnership with Absaugwerk

Powerful dust extraction is essential for the safety and health of employees, as well as the performance of the machine. With the extraction units from our partner Absaugwerk, you can be assured of clean air.

2022

Partnership with 3M

Timesavers opts for the best grinding results possible, and therefore offers high quality abrasive belts from 3M. Their grind technology is remarkable.

2023

Introduction of the 12 RB series

This is Timesavers' smallest rotary brush machine! With a working width of 300 mm, it is perfect for deburring, rounding and finishing small parts.