Sharp edges and corners on sheet metal can be caused when metal parts are stamped, punched, milled or on parts cut by laser, plasma, water jet or guillotine shear. These sharp edges can cause serious injuries during the processing by hand or during assembly. The edge rounding will not only protect the personnel from the sharp edges but also the machine that processes the product. Moreover, rounded edges are often needed due to health and safety requirements in sectors such as the food industry and pharmacy.

Surface treatments on sheet metal

When metal parts are being prepared for surface treatments, for instance coating or welding, it is required to have good edge coverage. Otherwise, the paint could come off.

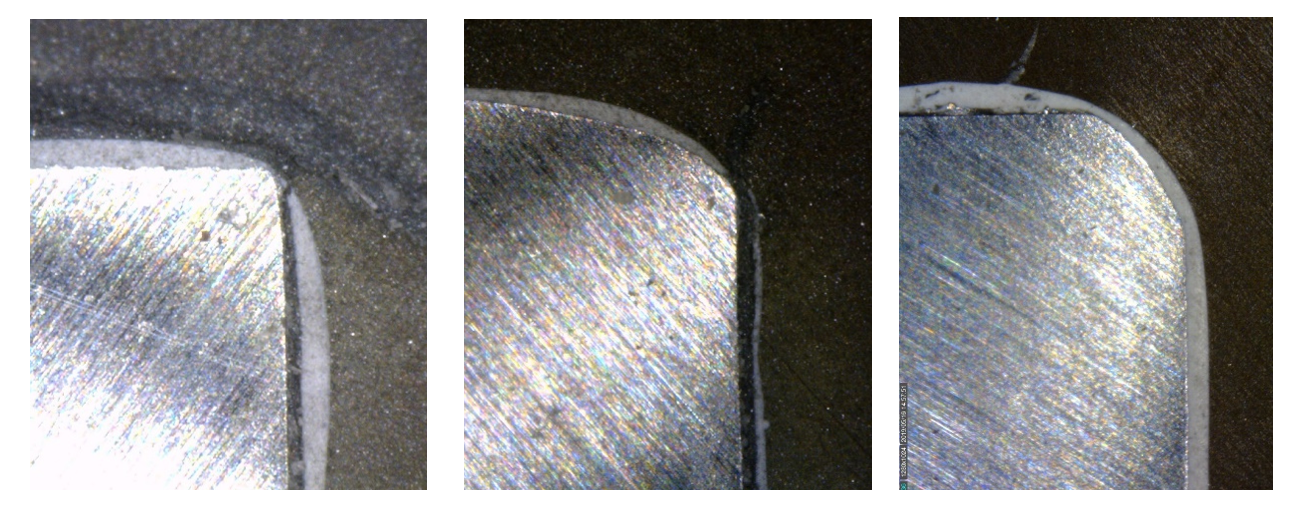

Rounded edges and corners to a certain radius make sure that the thickness of the paint layer is the same as on the rest of the surface. A radius is the angle of the bend, measured between the bent flange and its original position. In the photos below, you see how well the coating adheres to the part.

Sharp edge Rounded edge Edge with a radius of 2 mm

How does mechanical edge rounding take place?

Although edge rounding can be done with the use of manual electric grinding tools, the best quality is achieved with mechanical edge rounding. The consistency of the products will no longer depend on the skill per worker, but it is an automated process working with precision.

The corner rounding machine could have several attachments that can break the edge or even round the edge to a certain radius:

- Multi Discs; The machine can be equipped with multi discs that rotate in opposite directions. They create a large rounding and affect the part’s surface. Therefore, the discs also leave a quality finish.

- Rollers; Abrasive rollers that are used for deburring, can also break the edges of metal parts.

- Rotary Brushes; Rotary brushes are attached to a rotary carroussel and have abrasive flaps that are flexible, thus rounding the whole edges, while leaving the surface unharmed. Just a few scratches at most.

The results are uniform deburred and rounded edges. It is the best attachment to get a perfect radius. These rotary brush machines are available from compact 600 mm working width machine till a 1600 mm machine for the heavy-duty work.

Advantages of mechanical edge rounding

- It saves time, labour and costs compared to manual edge rounding.

- The metal part gets a uniform edge round that makes it suitable for coating, welding or other surface treatments.

- The machinery can achieve a radius of up to 2 mm.

- The processed sheet metal components are of high, consistent quality.

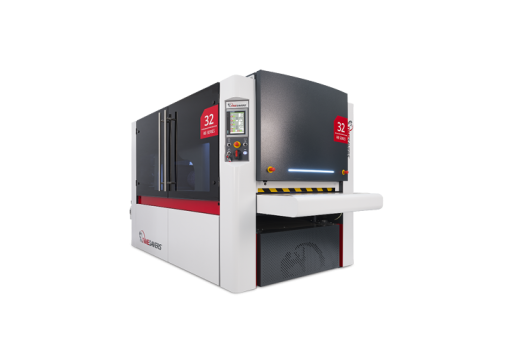

Timesavers edge rounding machine

Timesavers offers numerous solutions for edge rounding problems. The machine can process bigger parts or smaller ones, even as small as 50×50 mm. These small parts are kept in place by the machine’s contact rollers.

The most important innovation of Timesavers for edge rounding is the rotary brush. The rotary brushes create a uniform radius of 2 mm on different types of metal.

By precisely processing the metal components in a machine, the edges are all consistently rounded. The pieces of sanding paper hit against the sheet metal and round it. The result is an equal radius on for instance all contours of stainless steel steel, aluminium, zinc, etc.

Timesavers also offers different configurations, that can include additional application processes. In order to have a metal deburring machine and edge rounding machine, a belt and rotary brushes are required. This configuration is ideal for components with burrs and sharp edges.

The rotary brush edge rounding compartment can be also combined with a Scotch Brite belt which also makes it a finishing machine. In order to deburr the part and get a double-sided edge round with a finish, it must be rotated and run through twice.

You can configure a machine that corresponds with your wishes and budget. Let us know how we can be of help in your search for the perfect edge rounding solution.

About edge rounding

+

Why do you need an edge rounding machine?

Manually rounding the edges of metal is a time-consuming work and requires skill in order to get consistent quality. However, an edge rounding machine is able to process multiple parts at once with consistent edge rounding quality at much higher speed.

+

How to round the edges of metal parts?

You can round the edges manually by using abrasive grinding paper, but for better results it is recommended to round edges mechanically. Abrasive rotary brushes are an excellent solution to create a consistent radius on your parts. Discs are used if only a slight edge break is needed.

+

How do you get a uniform radius?

A rotary brush can grind the edges of any metal part to a uniform radius. The brush flaps with abrasive material are flexible and only hit all the edges when it rotates, while leaving the surface unharmed.

+

How do you measure a radius?

The best tool to measure a radius is a laser scanner. It comes with a program that shows the exact radius and can provide a drawing of the rounding.