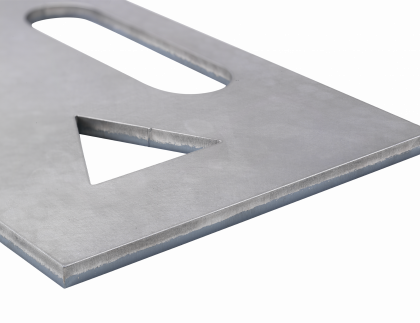

Before coating or welding or other surface treatments, the side of a metal part must be clean and without laser oxide. The laser oxide removal brushes developed by Timesavers can be used to remove the laser oxide layer without damaging the metal part. More information is found in the knowledge base about laser oxide removal.

Your problem, our solution

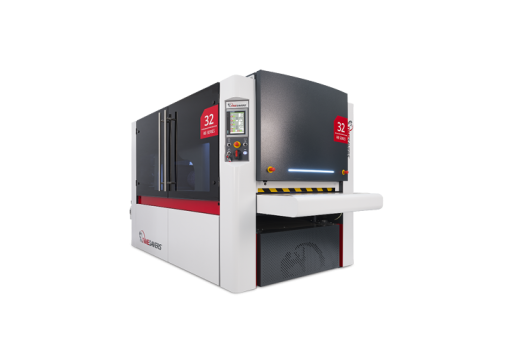

Save time with our laser oxide removal solution

Save time with our laser oxide removal solution

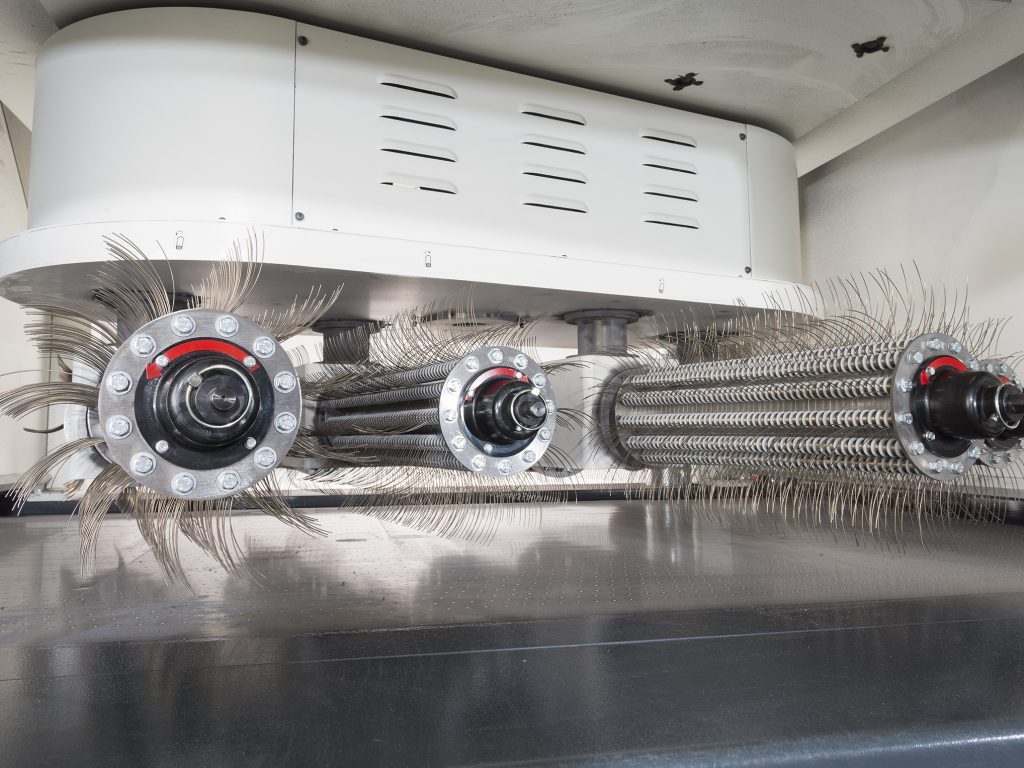

Oxide skin occurs on metal surfaces and stainless steel when oxygen is used during the laser cutting process. Although the oxide layer is protecting the aluminium surface from corrosion, it must be removed for subsequent powder coating processes or welding. Therefore, Timesavers has developed a perfect solution to remove contaminants and oxides, from the surface, as well as from the sides of the laser cut product. While some companies use laser cleaning or polishing or rubbing compounds for deoxidization, Timesavers is using steel wire brushes that serve as the perfect oxidation remover. The brushes from Timesavers save time, because they remove the oxide film in a dry process and thus there is no need for rinsing the product afterwards. Additionally, the use of the oxide removal brushes is more durable and better for the environment compared to chemicals.

Laser oxide removal in combination with edge rouding

What is the right solution for you?

By answering 5 simple questions, we lead you to the right machine.

FAQ about removing laser oxide

+

What is laser oxide?

Laser oxide is a thin, shiny layer caused by cutting processes that use CO2 as an assist gas. The laser oxide, also called oxide skin, can be found around the cuts of the steel part. An oxide layer makes the products unqualified for coating or welding, since the layer can flake off and lead to paint or weld failure.

+

What is laser oxide removal?

Laser oxide removal is the removal of the thin, shiny layer on steel parts, with the use of chemicals or brushes.

+

Why remove laser oxide?

Oxide layers on steel parts are caused by CO2 lasers and need to be removed in order to ensure coating or welding quality.

+

How to remove laser oxide?

Oxide skin can be manually scraped off, or removed with the use of steel wire brushes in a machine. The brushes hit the oxide skin off the parts within seconds.