FOR ULTIMATE DEBURRING, FINISHING, EDGE ROUNDING, LASER OXIDE AND HEAVY SLAG REMOVAL

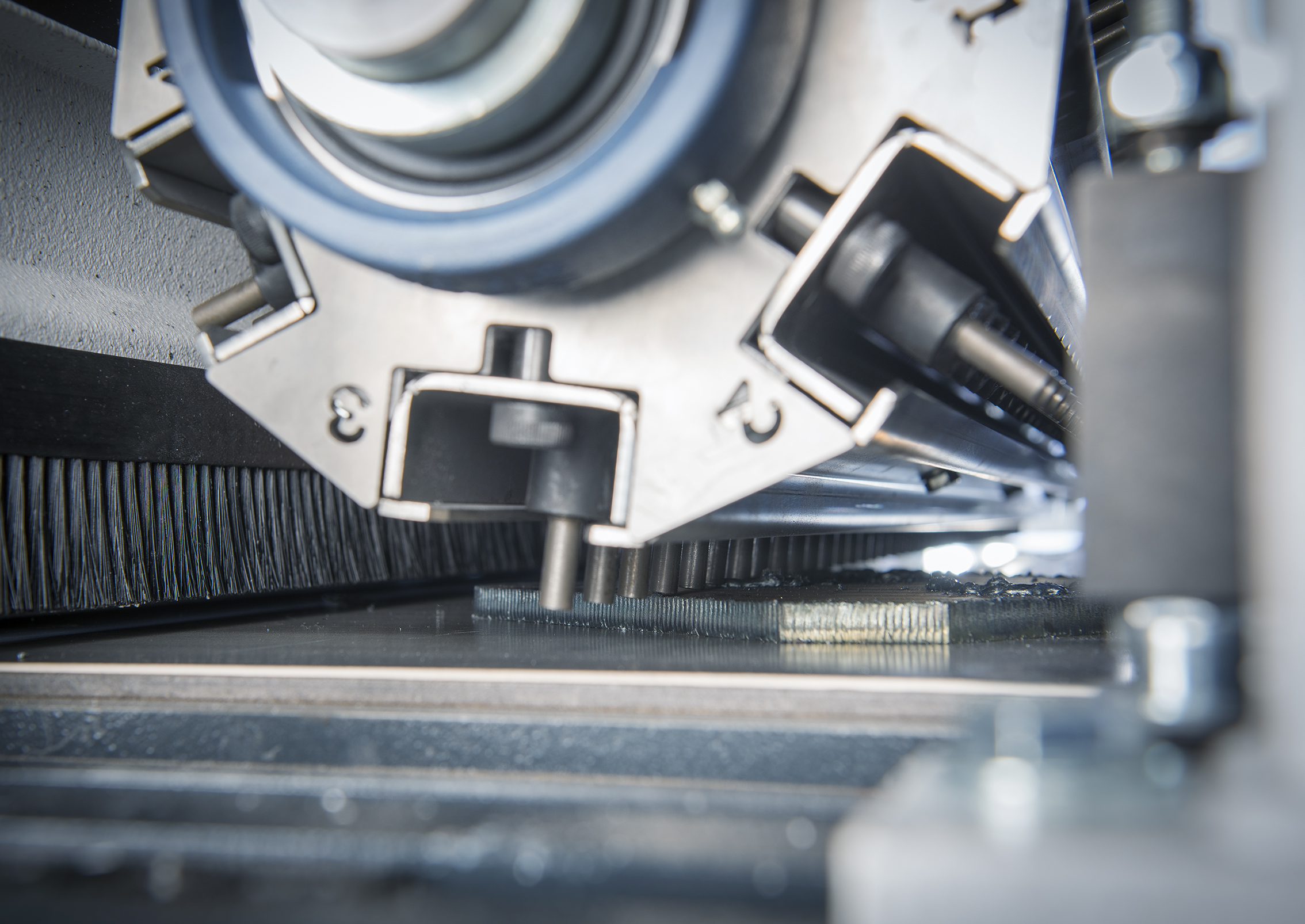

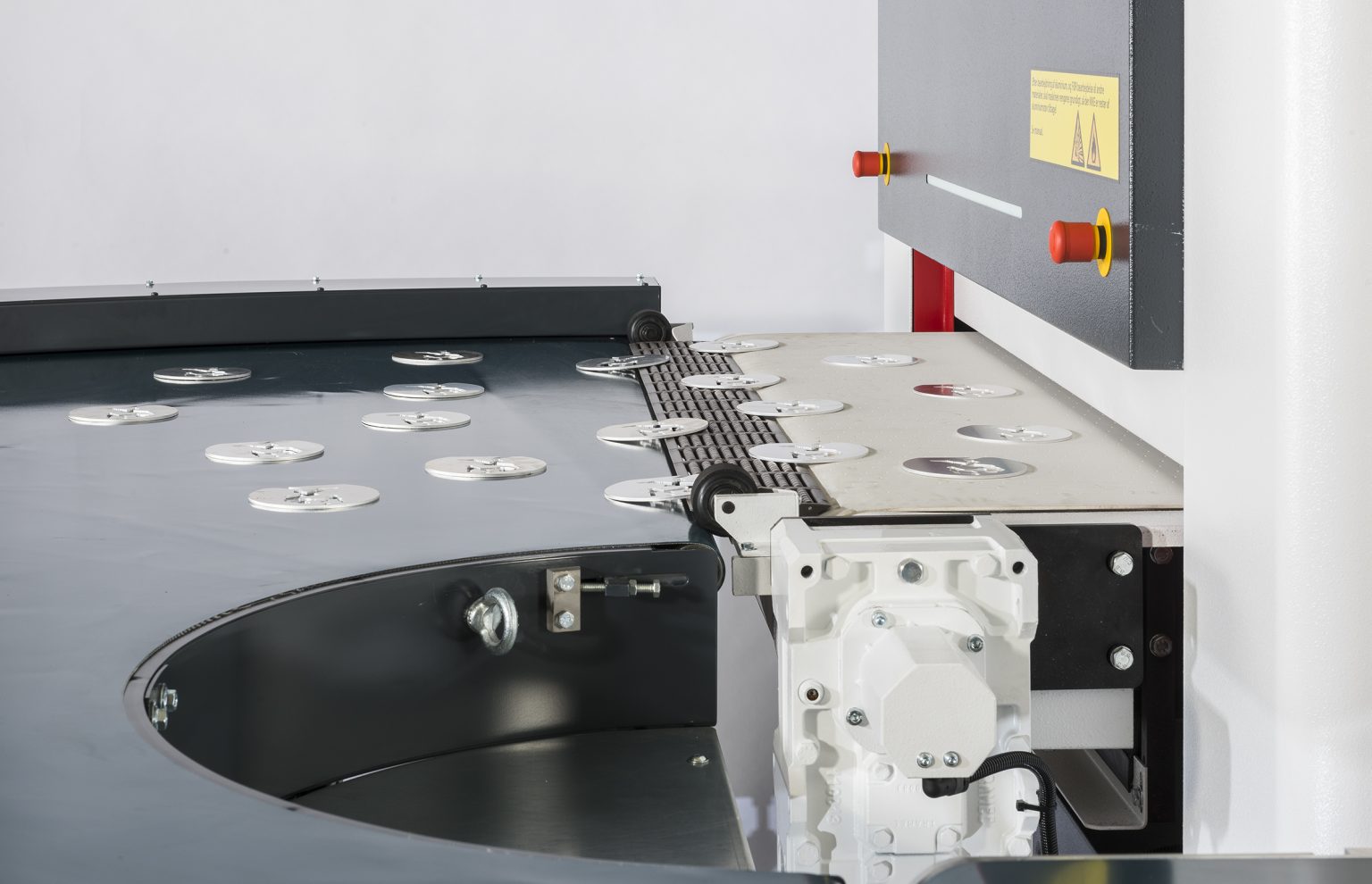

The 42 RB series offers the solution for manufacturers who supply premium quality products. This top quality is achieved through a multi-rotating brush head with eight abrasive flap brushes that deburr uniformly and round the edges of the metal perfectly. This machine can achieve a radius of 2 mm on mild steel and even more on softer material like aluminium.

Play

Play

Applications of the 42 RB series

Applications of the 42 RB series

Interested in the application results of the 42 RB series?

Interested in the application results of the 42 RB series?

Order the sample box to experience the application results that can be produced by the 42 RB series.

Save 50% of the time required for traditional machining of laser parts.

Processing products with the Timesavers 42 RB series offers huge benefits such as:

– High quality and rapid production

– Large variation of sheet thicknesses possible

– Deburring, rounding and finishing in one processing step

Manual method

42 RB series

What makes the 42 RB series unique?

Create the most uniform radius with the 42 RB series

Create the most uniform radius with the 42 RB series

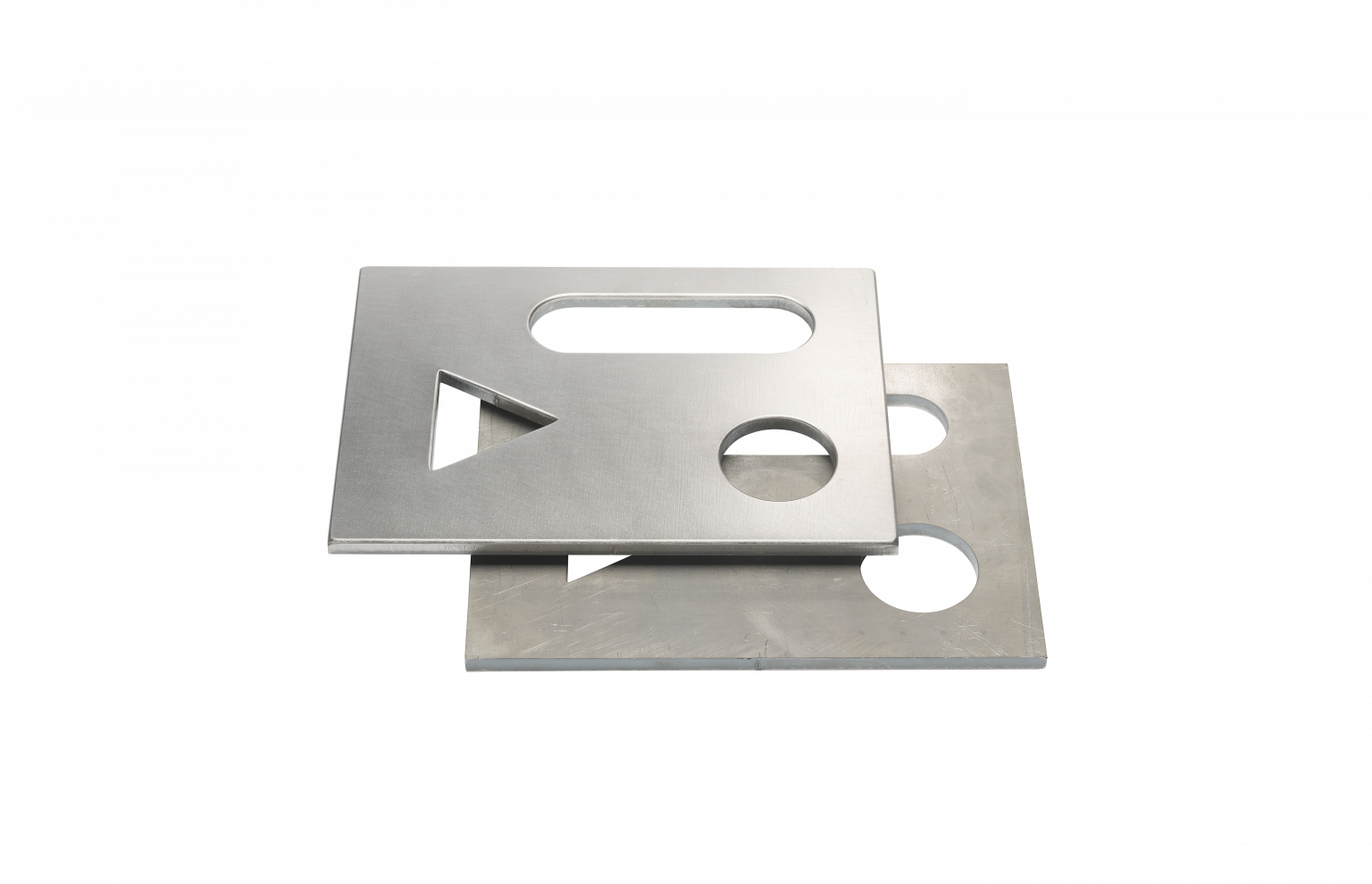

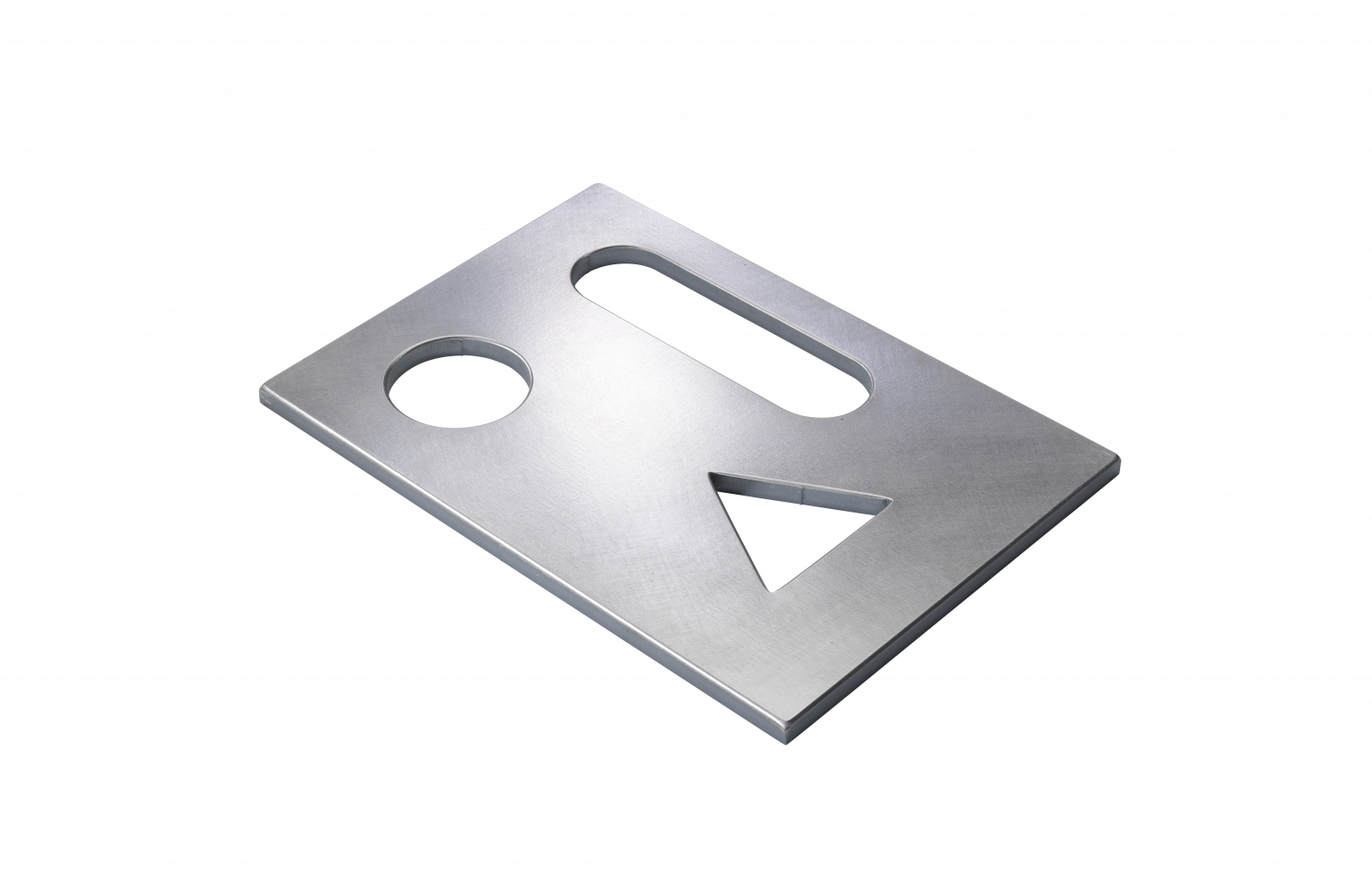

The 42 series rotary brush machine is the most suitable machine on the market to create a uniform radius of 2 mm on different types of metal. By precisely processing the metal components in a machine, the edges are all consistently rounded. The pieces of sanding paper hit against the sheet metal and round the edges until an equal radius is created on for instance stainless steel steel, aluminium, zinc, etc.

Available configurations

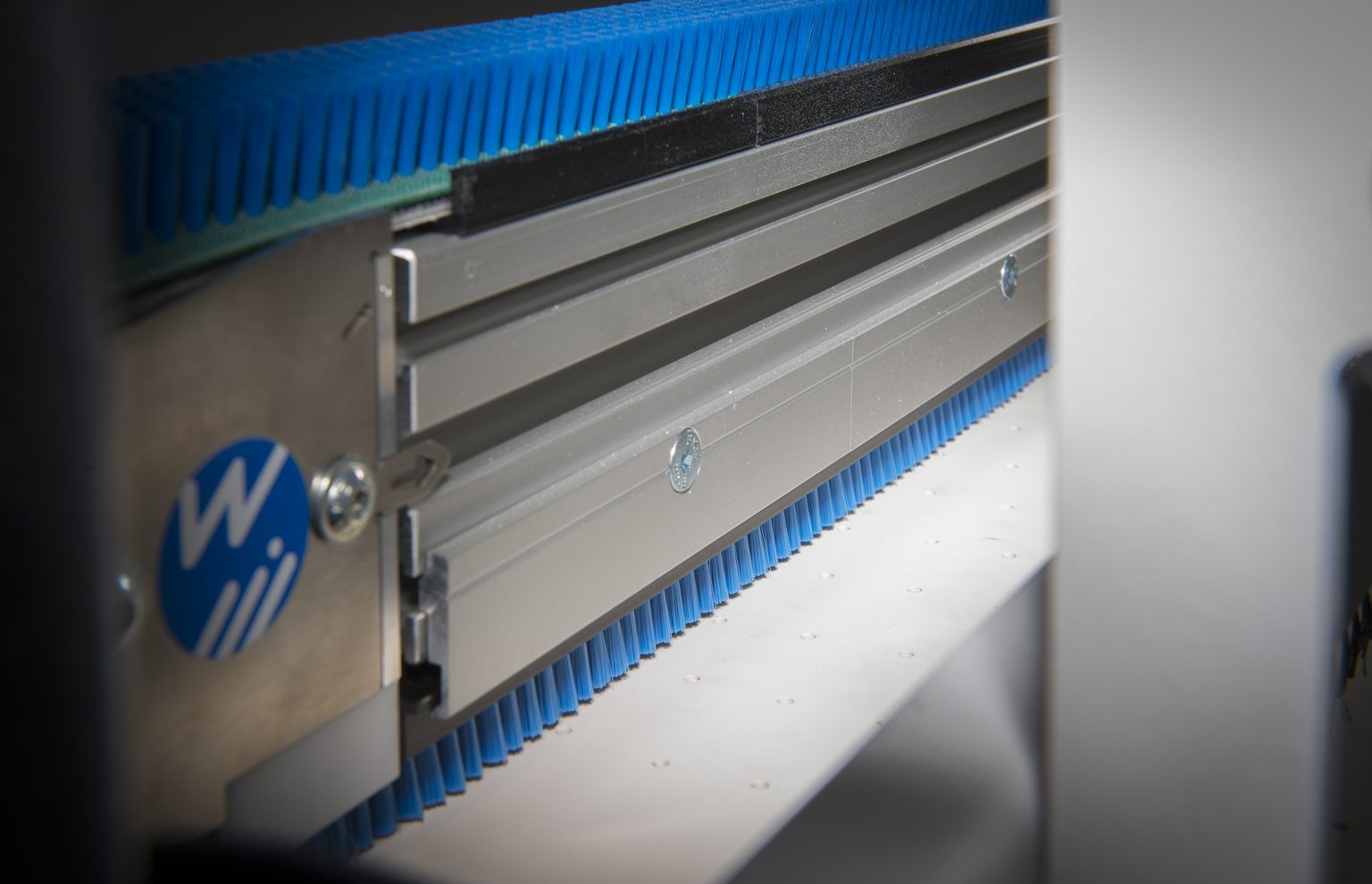

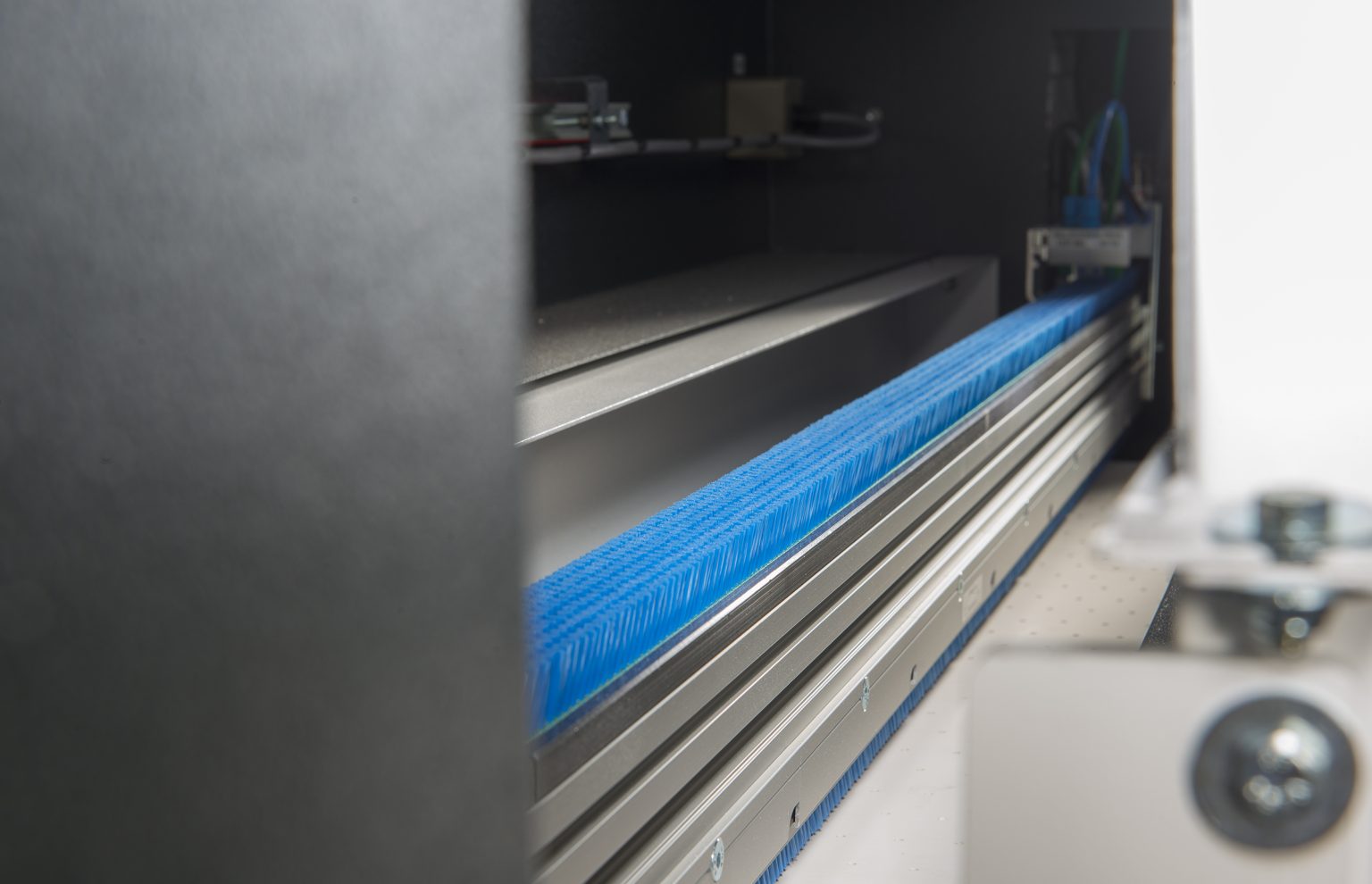

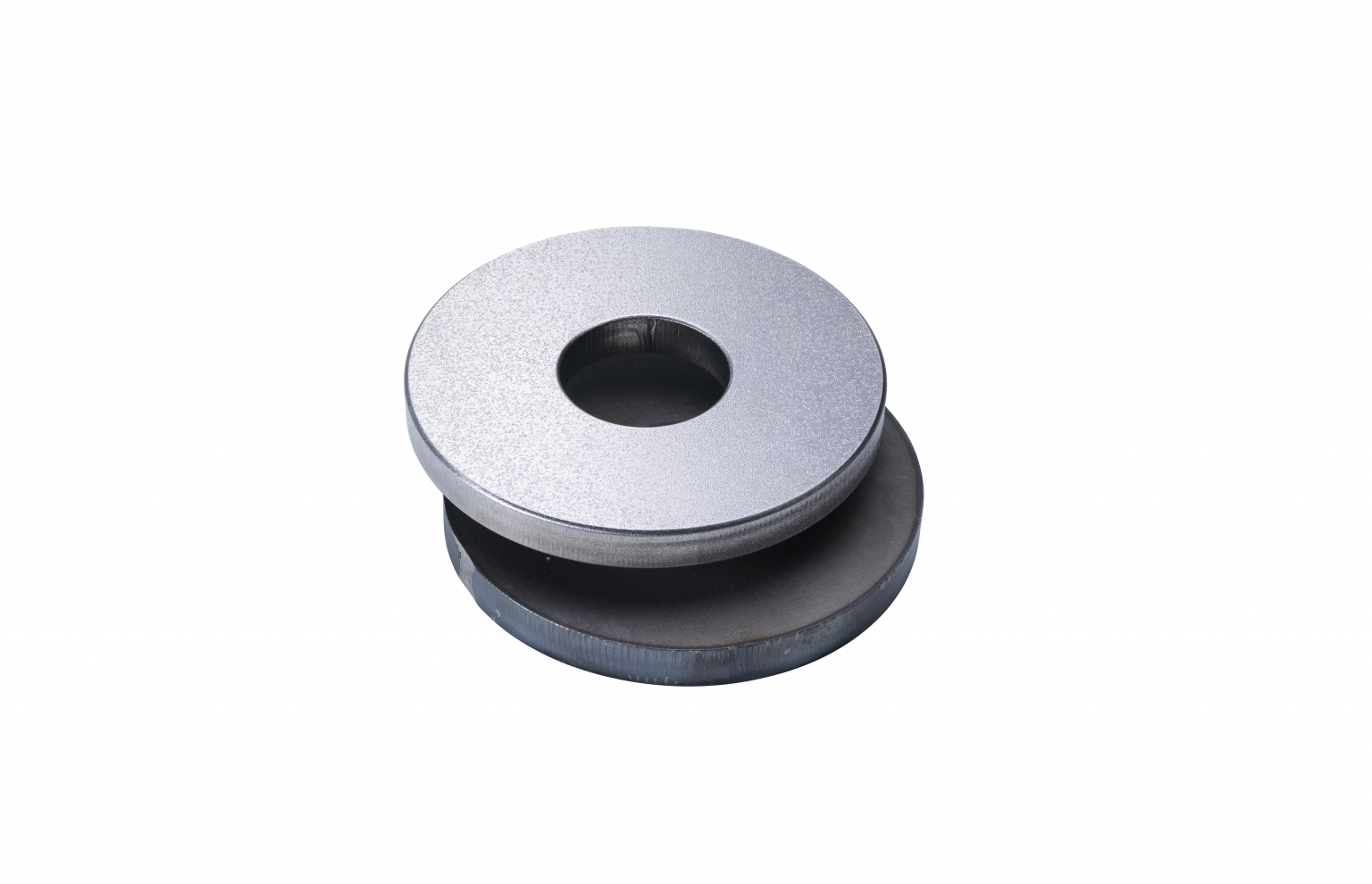

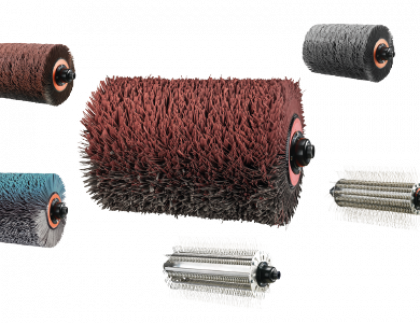

Original tooling

Original tooling

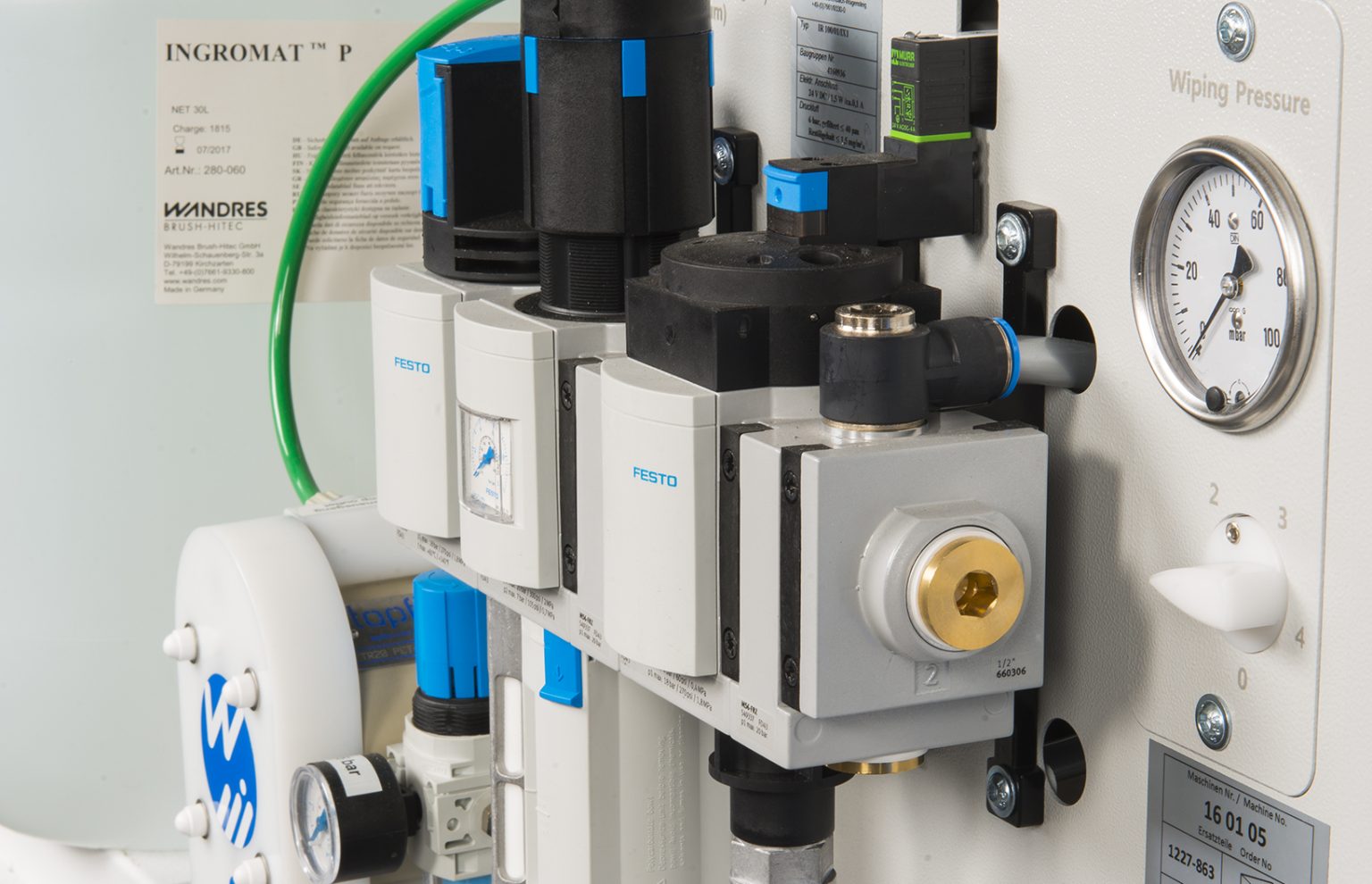

Timesavers provide you original spare parts and tooling, that ensures that your machine continues to perform with the best results.

More info? Get in touch.

Timesavers area sales managers are the application experts with a lot of experience. They know like no other how to help you find the best solution to your problem.