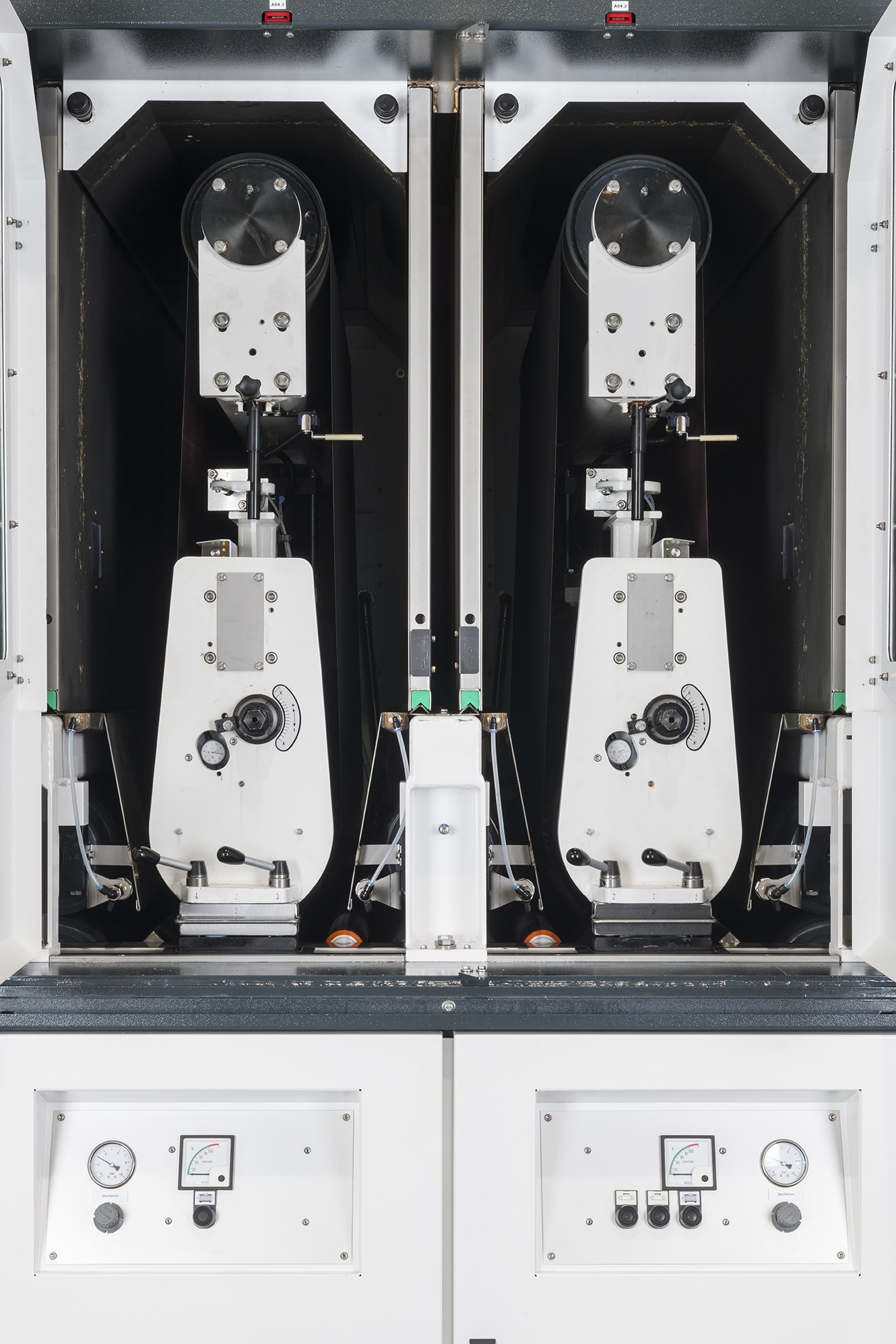

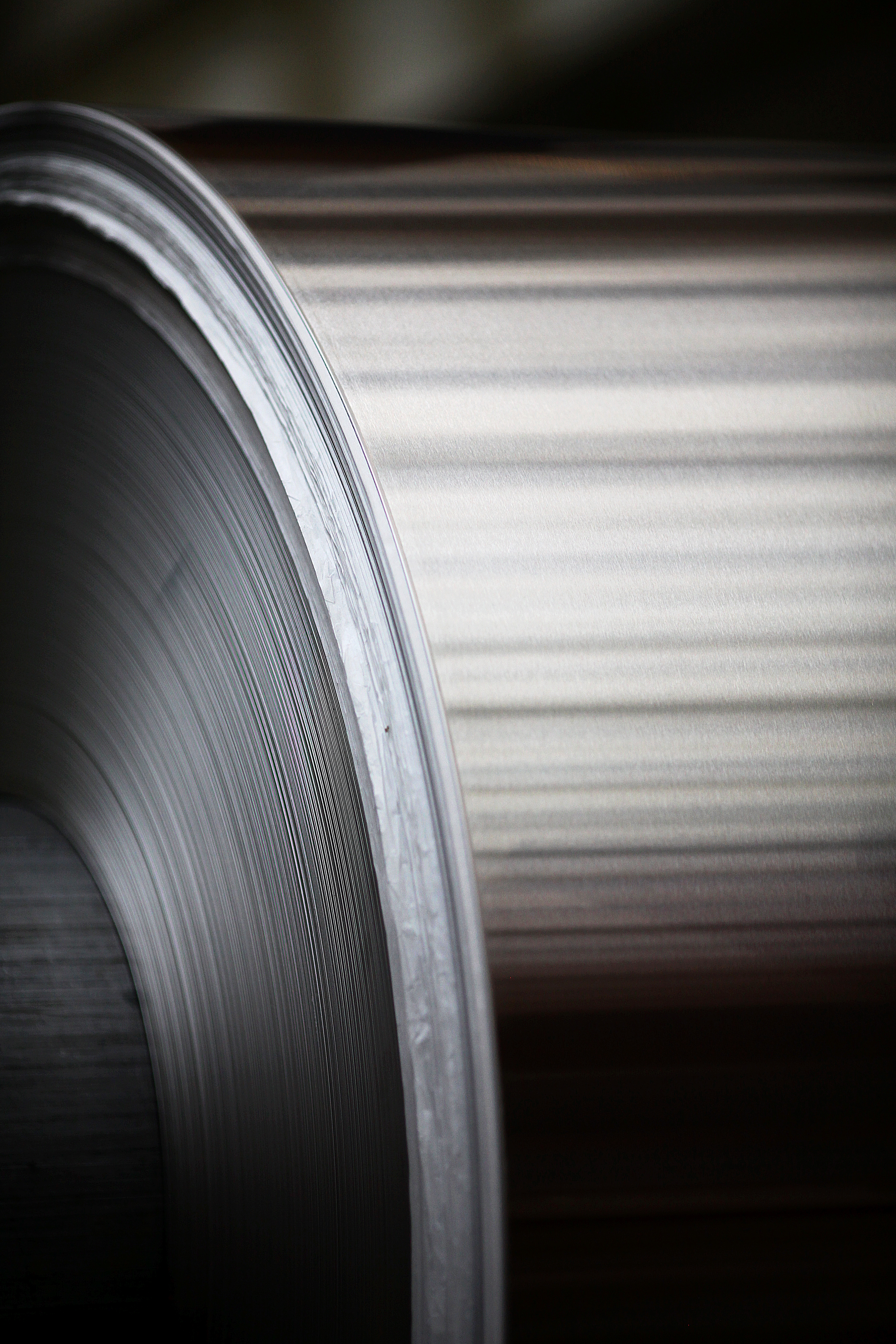

A complete wet 'coil-to-coil' line

We offer our 71 series for finishing of sheet material rolls. The machine has a production speed of up to 30 m/min and delivers a perfectly finished end result. The 71 series has been developed to perform: day-in, day-out, year-in and year-out.

Finishing

Play

Play

+5

Solutions of the 71 series

Solutions of the 71 series

+

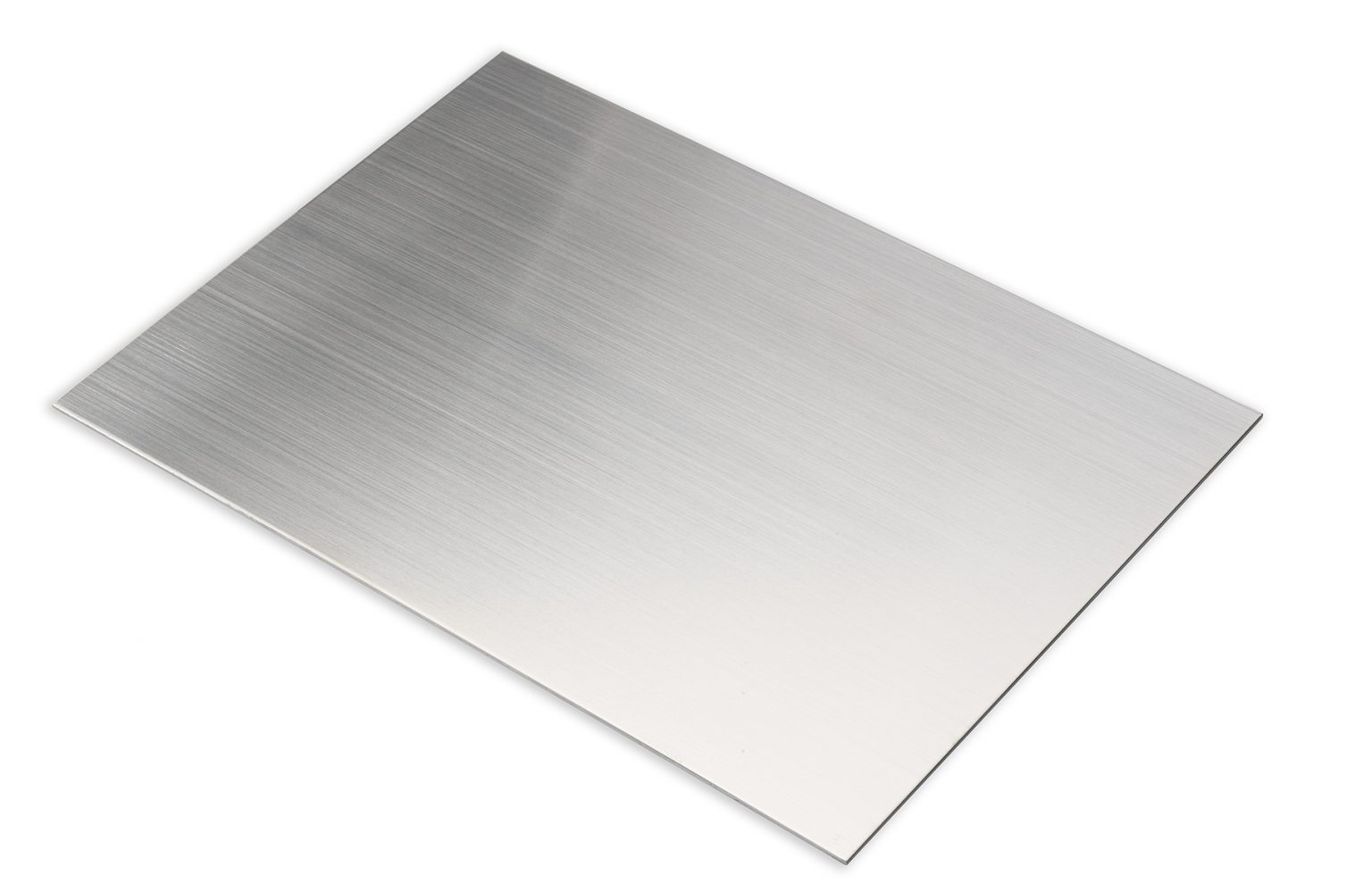

Hairline finish

+

Duplo finish

+

Microlon finish

+

No. 4 finish

What makes the 71 series unique?

Coil-to-coil' and sheet-to-sheet

Long scratch hairline finishing

Can be purchased as a turnkey project

Available configurations

More info? Get in touch.

Timesavers area sales managers are the application expert with a lot of experience. They know like no other how to help you find the best solution to your problem.