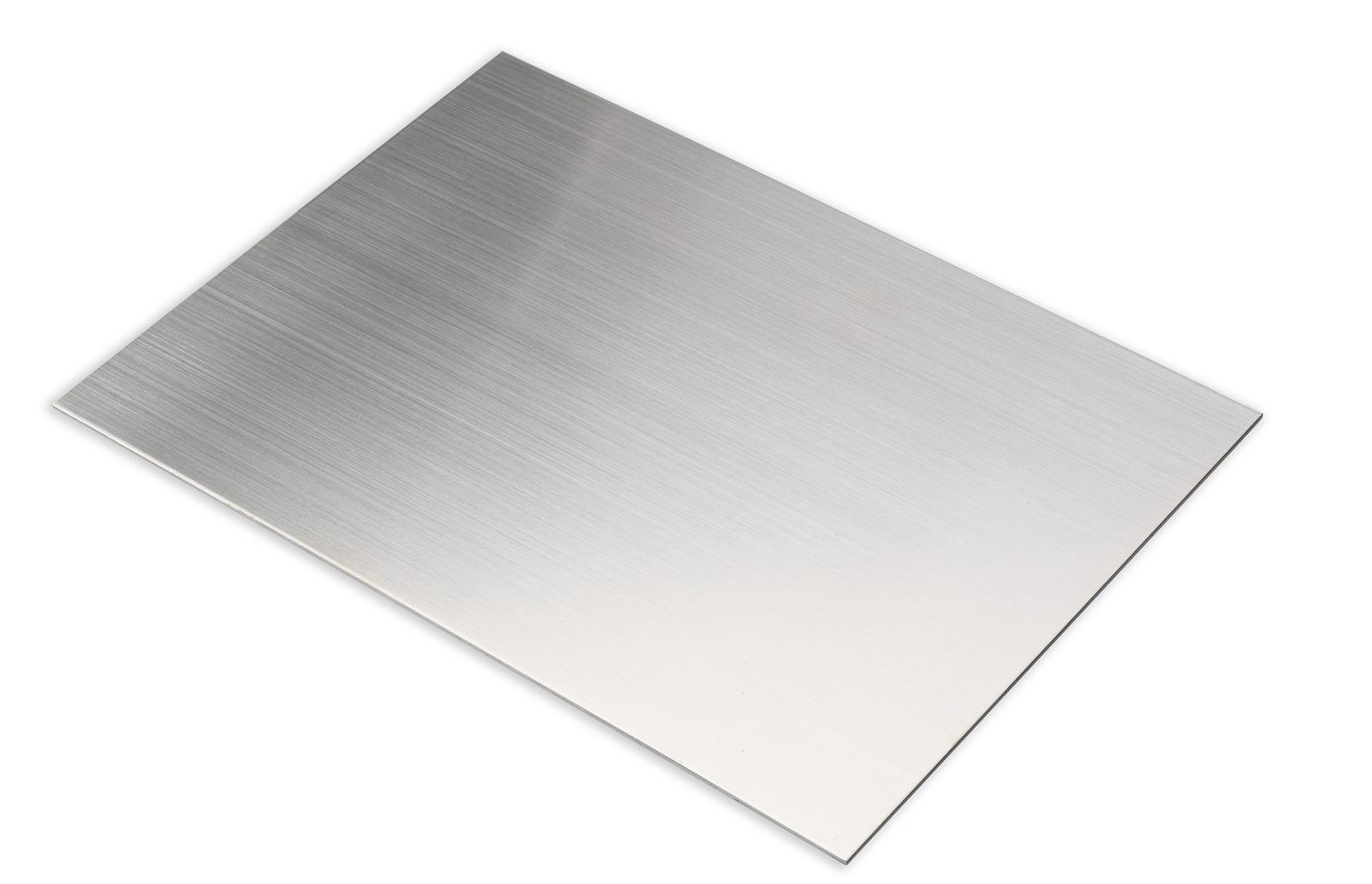

Deburring and finishing of a broad range of materials

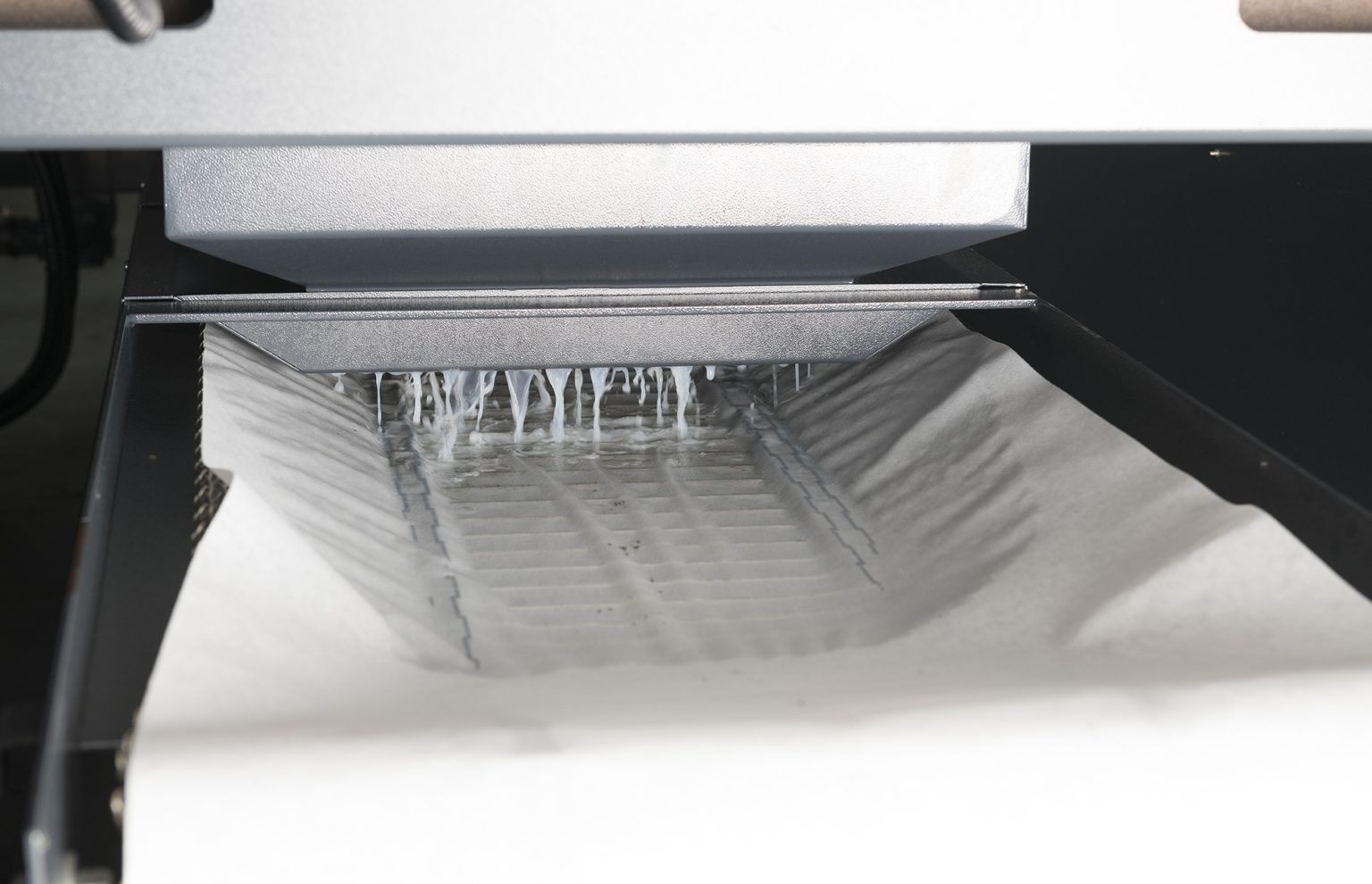

The 31 series has an integrated coolant filter system to cool the metal products during machining. This ensures that the abrasive belt’s service life is extended. Because of the wet-working system, filter paper is used to filter the coolant before it is recirculated. At the end is an integrated dryer, that dries the metal products while they are exiting the machine.

Deburring

Finishing

Play

Play

+6

Applications of the 31 series

Applications of the 31 series

+

Hairline finish

+

Microlon finish

+

NO. 4 finish

+

Duplo finish

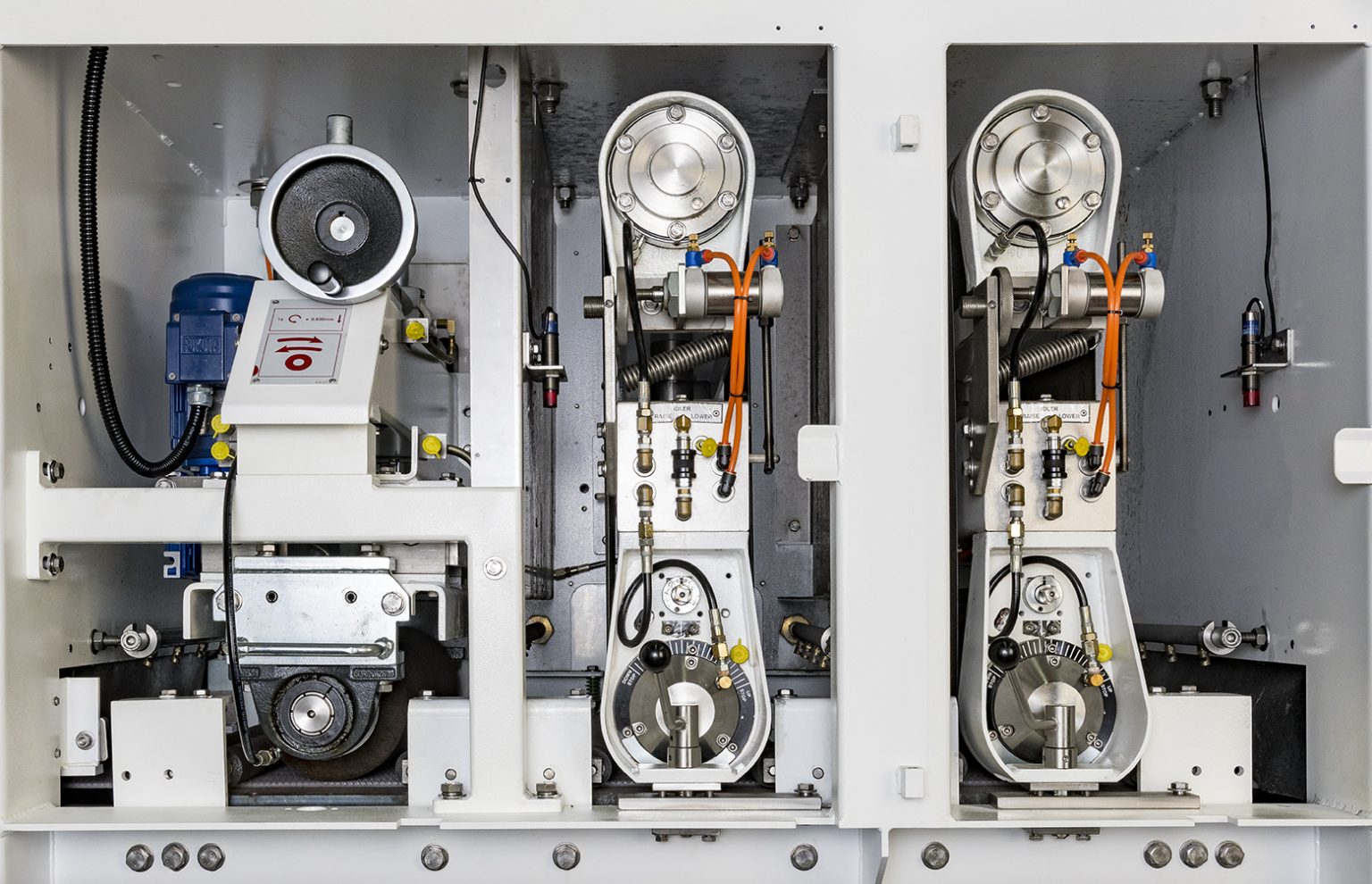

What makes the 31 series unique

wet deburring and finishing of surfaces in one pass

suitable for stainless steel, steel, aluminium, titanium etc

ease of use thanks to a simple control panel

AVAILABLE CONFIGURATIONS

more info? get in touch

Timesavers area sales managers are the application expert with a lot of experience. They know like no other how to help you find the best solution to your problem.